Expected to be used outside, wood has to reach a suitable performance according to swelling. The anti-swelling efficiency of long treated samples has been evaluated around 70%. Even samples subjected to water leaching, which is susceptible to occur in the environment, show the same anti-swelling efficiency values. This is due to the occurrence of oligomers into the cell walls, around cellulose microfibrils where water uptake takes usually place, and promises a good outside stability.

Water leaching has been quantified as around 16% oligomers weight loss on the oligomer content basis, after one week of leaching. It has been found that acid concentration of removed water increases in time along with the gradual hydrolysis of lactic acid chains in the wood cell walls.

1.3 Mechanical performance

Mechanical performance have been assessed in terms of bending strength (oB), compression strength (oC), shearing strength (fy), and hardness (Brinell HB and Monnin N normalized methods). Table 1 summarizes densified samples strengths.

|

Specimen |

cb (MPa) |

cc (MPa) |

fy (MPa) |

N |

|

Beech control |

120 |

72 |

11.9 |

|

|

Non catalysed treatment |

142 |

97 |

15.3 |

|

|

Sulfuric acid catalysed treatment |

50 |

107 |

19.4 |

|

|

Tin octoate catalysed treatment |

86 |

92 |

19.3 |

|

|

Pine sapwood control |

170 |

47 |

2.7 |

3.7 |

|

Non catalysed treatment |

146 |

66 |

2.2 |

3.3 |

|

Sulfuric acid catalysed treatment |

172 |

64 |

1.1 |

7.8 |

|

Tin octoate catalysed treatment |

181 |

54 |

1.2 |

5.2 |

Densified composite shows a different mechanical behaviour according to the species and treatment.

Pine samples bending strength is not affected by catalysed or non catalysed treatment. Contrariwise, catalysed treatments strongly affect beech samples. With every treatment on both species, the bending deflection is decreased, which translates the brittleness of the material. This is not necessarily a limitation. Especially in the case of pine samples, where the same bending force leads to break but with less deformation.

Compression strength parallel to the grain is increased by every treatment on both species, with reduced deflection as well.

Shearing strength test performed on pine samples confirms a strong embrittlement of middle lamella. Indeed, shearing strength is strongly decreased by catalysed treatments. Monnin hardness is strongly increased by catalysed treatment.

Densified composite obtained by non catalysed treatment shows improved or at least unchanged mechanical properties.

Densified composite obtained by catalysed treatment shows improved compression strength and Monnin hardness, but an obvious degradation of fibres cohesion has occured.

Mechanical assessment of softened composite has been used to quantify the structural degradation. Table 2 summarizes softened samples strengths.

|

Specimen |

(MPa) |

fV (MPa) |

N |

|

Beech control |

120 |

11.9 |

|

|

Non catalysed treatment |

77 |

2.7 |

|

|

Sulfuric acid catalysed treatment |

15 |

5.3 |

|

|

Tin octoate catalysed treatment |

6 |

1.5 |

|

|

Pine sapwood control |

170 |

2.7 |

3.7 |

|

Non catalysed treatment |

75 |

2.3 |

0.3 |

|

Sulfuric acid catalysed treatment |

14 |

1.1 |

1.8 |

|

Tin octoate catalysed treatment |

28 |

101 |

1.3 |

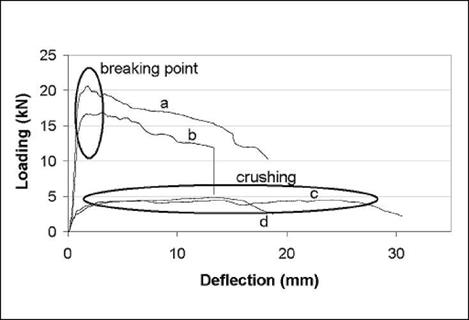

Compression strength cannot be assessed on softened samples because no breaking point is ever reached (Figure 10). Instead, crushing happens progressively along the test.

Bending strength, shearing strength and hardness are strongly decreased by every treatment, even more by catalysed treatments.

|

Fig. 10. Compression-breaking curves of pine control specimens (a and b) and specimen subjected to short catalysed treatment (c and d) |