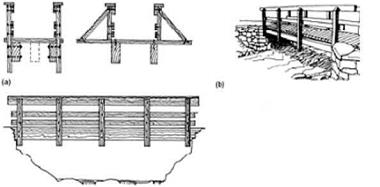

This is more appropriate in less wild settings. Two or three beams can be sawn out of solid wood, being proportionately deeper than wide, laid parallel to each other with a decking of sawn boards fixed across them. Some bracing to prevent differential movement between the beams might be needed, with handrails bolted to the outer beams.

If beams sawn from single timbers are unsuitable, or unavailable for the loading or the span, then laminated beams can be used instead. These are made from narrow strips of timber glued in layers to form a beam. Once again, larger rather than smaller-scale sections look better in most landscapes.

Steel beams

Steel beams might be used where the span is too large to be bridged economically with timber. If these are made of ‘Cor-ten’ steel or galvanized and left to weather, or painted a dull earth tone, they can be acceptable. Wooden decking and handrails treated with preservative can be provided so that natural materials are more dominant when seen from the trail. Such bridges are very durable and have a long life compared with all-timber structures.

Steel decking and handrails may have a place in certain circumstances, where durability in harsh conditions is needed, or low maintenance is a priority

|

Designs of sawn timber beam bridges: (a) Construction methods include handrails either fixed to the supporting beams or strengthened laterally using outrigger and strut. (b) A small beam bridge of good design and construction.

|

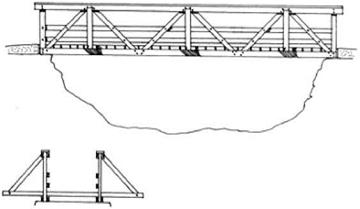

Truss construction is an acceptable

form of construction. It uses smaller-dimension timber than the simple beam bridge.

The truss also acts as part of the handrail.

and where a lighter all-steel structure might have less impact than a bulky wooden bridge. Sometimes nonnatural materials can help to emphasize the drama of

a natural scene. Expanded metal or steel grating can be used for the decking, with steel handrails and uprights infilled with tensioned wire.

Trussed beam construction can also use timber. Made of small wooden sections, bolted together on site, this type of bridge can be erected in areas where access is difficult. The handrail section becomes an integral part of the structure. Maintenance and repair involving replacement of individual sections is also possible without dismantling the whole bridge, as would be the case with a solid beam. A light steel truss bridge is being prototyped by Forest Enterprise in Britain using triangular lattice sections for the beams.