Supplies, and hardware

Consider the quality, grade, and availability of all materials needed to fabricate furniture as well as the width, length, thickness, and finished surface qualities of the materials as they are distributed. This process determines the necessary cuts and the yields of the materials needed. For example, % inch (1.9 cm)-thick medium-density fiberboard (MDF) is slightly thicker than % inch (1.9 cm)-thick plywood. Though plywood is available in 48-inch x 96-inch (122 cm x 244 cm) sheets, MDF is purchased in 49-inch x 97-inch (124.5 cm x 246.5-cm) sheets. Baltic birch plywood is generally available in 60-inch x 60-inch (150 cm x 150 cm) sheets. If there are any doubts regarding the true dimensions and characteristics of the materials you desire to use, be certain to ask the supplier, distributor, or fabricator.

Lumber purchased S4S (surfaced four sides) is dimensioned lumber and is sold in linear feet using fixed, nominal dimensions. Rough lumber boards are planed and jointed (surfaced) on two edges. They are also available in prejointed boards for a noticeable savings in cost. Thus, a 1 x 2 is % inch x 1І2 inches (1.9 cm x 3.8 cm) and a 2 x 4 is 1>2 inches x 3>2 inches (3.8 cm x 8.9 cm). Their fixed dimensions can also influence design.

Rough lumber, which ultimately gives the fabricator the most flexibility, is sold by the board foot, and is available in thicknesses measured in quarters of an inch and referred to as % , %, %, %, 104, and boards. One board foot is equal to the volume of lumber equivalent to 12 inches x 12 inches x 1 inch (30.5 cm x 30.5 cm x 2.54 cm) thick (144 cubic inches). Structural steel is purchased by the linear foot, thickness, and weight. Common stock profiles include flat bar stock, round tubing, bar tubing, square tubing, and angle. Plastic and glass sheet goods are purchased by the square foot, and pricing is based on type, thickness, and edge treatment. Granite and marble are sold in 14-inch (2 cm) and 114-inch (3 cm) thicknesses. A polished finish is standard on one side of stone slabs when

distributed, but honed, thermal, hammered, and flamed finishes are also available. Leather is sold in full – and half-hide sizes and in full-thickness, split, and suede finishes. Sheet metal is sold in sheets and in various gauges and alloys. Sheet metals generally require professional fabrication and tooling. Keep in mind that most retailers that sell lumber, metal, stone, and plastic will charge to make cuts.

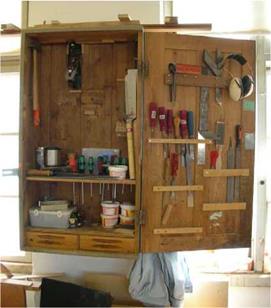

It is unrealistic to be dogmatic about what tools are needed to build furniture. The choice depends on a number of factors, including the experience and personal preference of the fabricator, the materials being used, available shop space, and financial resources available (Figure 8.3).

It is unrealistic to be dogmatic about what tools are needed to build furniture. The choice depends on a number of factors, including the experience and personal preference of the fabricator, the materials being used, available shop space, and financial resources available (Figure 8.3).

Many types of hand, power, and digital tools are used to make furniture. While good tools are often expensive, it is advisable to purchase and use quality tools because they are essential for producing quality results safely. As a rule, buy hand tools of superior quality and consider them all an investment.

Figure 8.3 Hand tools-craftsman’s wall cabinet for hand tools A list of hand tools for making furniture might include:

at Rud. Rasmussen woodshop, Copenhagen. Photography by

■ Adjustable block plane and jack plane

Jim Postell, 2006.

■ Awl, calipers, and a marking gauge

■ Metal cabinet scraper and a burnishing rod

■ Bevel-edge chisels: 1 inch (3 mm), >4 inch (6 mm), 28 inch (9 mm), Vi inch (12 mm), 34 inch (18 mm), and 1 inch (24 mm)

■ Mortising chisels: X inch (6 mm), 28 inch (10 mm)

■ Firm-edge chisels

■ Wooden mallet

■ Japanese saws (these "backsaws" cut on the pull) (Figure 8.4)

■ Coping saw

■ A set of countersink and high-speed steel drill bits

|

■ A true square

■ A speed square

■ A combination square

■ Sliding bevel

■ Steel straight edge (30 inches [76.2 cm] with units visible) and a flexible steel ruler

■ Marking knife

■ Bench vise (wood)

■ C-clamps (6-inch [15.2 cm] and 10-inch [25.4 cm] length)

■ Sash or bar clamps (30-inch [76.2-cm] length)

■ Framing corner clamps (minimum of four)

■ Stones for sharpening cabinet scraper and chisels

■ Level (24 inches [61 cm])

■ An assortment of hand screwdrivers (flat-head, Phillips, and square-head), pliers, sockets, and wrenches

■ An assortment of fasteners

■ A tape measure

A list of power tools for making furniture might include:

■ Belt sanders (24 inches [61 cm] long 3.3 inches [7.6 cm] wide)

■ Disk sander (13 inches [33 cm])

■ Oscillating spindle sander (Figure 8.5)

■ Orbital sander

■ Routers (and a small hand-held trim router)

■ Table router

■ Table saw

■ Shaper

■ Drill press

■ Powered hand drills

■ Air compressor

|

Figure 8.5 Power spindle sander. Photography by Jim Postell, 2006. |

■ Cut-off saw

■ Panel saw

■ Jointer (6-inch [15.2-cm] minimum)

■ Planer (13-inch [33-cm]-width minimum)

■ Wood lathe (36 inches [91 cm] long)

■ Metal lathe (36 inches [91 cm] long)

■ 3-axis mill machine

Shop supplies might include carpenter’s yellow glue, contact adhesive, polyacrylic, tung oil, Danish oil, or lacquer spray finishes, as well as sandpaper, screws, brads, finish nails, pencils, soap, beeswax, clean rags, and dust masks.

■ Yellow carpenter’s glue generally works better than white polyvinyl acetate (PVA) wood glue, but care must be taken in its application. To avoid making a mess in the application, having an abundance of damp rags on hand is suggested. Proper clamping pressure is also very important.

■ Pencils need to be hard enough to give precise fine lines but soft enough to be seen and not leave an impression on the wood. 2B pencils and 7-mm drafting pencils with 2H lead work well.

■ Marking knifes are more accurate than pencils and provide a precise cut in the wood to guide work with chisels.

■ Dust masks, ear protection, and protective eyewear are important safety measures. Working with wood and other materials generates fine dust and chemical fumes. The noise from power tools and compressor generators is damaging to the ears. Eyes are susceptible to fine particulates floating in the air, as well as to flying pieces of wood or metal from cut-off saws, sanding belts, and many other sources.

In addition to the necessary supplies, power tools, and hand tools needed to make furniture, a good horizontal work surface is essential in any furniture shop. Purchase or build one with a flat, sturdy top and a well-engineered base. Working at waist level is the conventional standard to use in determining the height of a workbench. Generally, 34 to 36 inches (86.3 to 91.4 cm) is a good workbench height.

Purchase additional high-quality tools as needed. It takes time to secure a set of tools and develop a sense of comfort, safety, and productivity with them (Figure 8.6).