|

|

Companies in business-to-business (B-to-B) markets often look at innovation as a consumer-driven revolution and not as something that applies to them. Their primary customers have been all about price and functionality, not lifestyle and desire. Because only one company can be the cheapest and most price-driven, commoditization stifles growth; these companies must find the power of innovation. Now the same high-value user experience is starting to be expected even for business-to-business products and services. Meeting these expectations requires not simply research and development but also a thoughtful strategic plan.

Trenton, NJ. It was a evening in November. Joey Russo and his team were getting in place for a long night. They would have 12 hours to get their work done and then inspected so that the day crew could move on to the next segment of pipe. Every day, the day crew relines decaying sewer pipes. Every night, Joey and his team surgically “cut the laterals.”

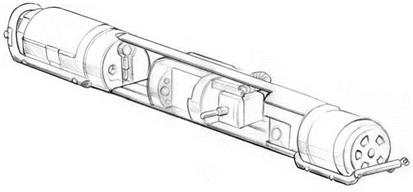

in every major city in the developed world, the sewers are more than 50 years old. The original piping was mostly clay-based, a material that becomes fragile and susceptible to cracking with age. Sewer pipes are typically 8 inches in diameter, too small for humans to physically enter to repair. There are two approaches to rehabbing sewer lines. The oldest is to dig up streets and yards to gain access to the pipes and replace them. This approach is prohibitively expensive and undesirable for everyone who lives in the neighborhood. The second, noninvasive procedure is to pull tools through the pipe. These tools are used to lay out a liner and then cut out the openings that connect the main pipe to the outlet to the homes, called “laterals” in the industry. The process is still essentially manual. Locations for the laterals are mapped out ahead of time, and a machine with a camera and cutting tool is then pulled through the pipe with a winch and is stopped at the locations that have been mapped. A skilled person like Joey then sits in a truck and looks at a video monitor that shows the location where the lateral is to be cut. (The liner has a dimple in it where the pipe coming into the main pipe intersects.) The person in the truck controls the cutter and watches the dim and colorless images on the monitor as he directs the machine to cut the lateral. The process is slow and tedious and takes years of experience to master, but it is instrumental to the success of the operation. Although this approach is preferable to brute-force digging, it does have its downsides. First, this expert lateral cutter demands a hefty salary (in some cases, more than $100,000). Second, this person and the equipment are the bottleneck to the speed of opening the pipes that lead to people’s houses. Third, the crew has up to 12 hours to open the lateral, or else sewage backs up into the house, forcing the sewer rehabber to quickly dig up the yard and open the pipe while irate homeowners look on.

Joey is that master cutter. He is often away from home at night, but the salary is worth it. His boss, Sal, knows Joey can jump ship and go to another company at any time, so sal has to make sure he treats Joey well. Sal is nervous because Joey is not easy to replace, and if he is sick or leaves, Sal will not be able to get the jobs done. Joey’s apprentice does not have enough experience, and Joey is not interested in giving him on-the-job training to create his own competition. Even though Sal does not have to stay and direct the night crew, he often loses sleep hoping that the morning will bring a completed section of cut laterals. Sal loses a small fortune if the laterals back up because they are not cut in time. He faces crews showing up with nothing to do if the laterals do not pass inspection. His agita is so bad that it prevents him from eating his favorite foods, and his blood pressure is off the charts if he fails to take his medication. Whereas the day crew’s work is important, the night crew critically impacts both the physical output of the business and its income statement.

Everyone had thought the liner technology was the perfect answer when it was invented. When he bought the business, Sal was told how much pipe could be lined and how profitable the business was. The lateral cutting seemed like a small part of the operation, with a specialized cutting tool to do the job remotely. But a large chunk of the profits go to Joey and his team. Plus, his current cutters break down all the time, so the crew has to travel with spare parts and be expert repairmen on-site. The business is really not that profitable after all. Sal would love a better pipe rehab process.