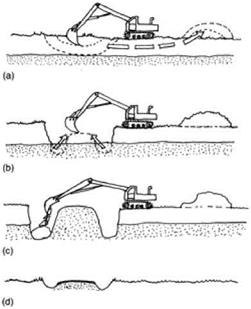

As a last resort in the worst places, where peat cannot support a raft, causeways can be constructed. If there is a subsoil the peat can be removed down to it and set on one side. Soil is then excavated along both sides of the proposed path route and piled in the middle until it rises to the level of the desired path. It is firmed with the excavator (backhoe) bucket. The excavated peat is put into the holes along both sides and covered in turf. Side drains should be left unturfed. This method produces a very firm path. It may, however, disrupt the hydrology of the peat and so be unacceptable in some places.

Boardwalks

If the ground is boggy with open pools of water, or too fragile to withstand foot pressure or a constructed path like those described above, then a timber boardwalk is a better option. These can be expensive to construct and maintain, but they might be the best option in terms of site protection. They are also exciting to walk along, and they have the added advantage of preventing people from straying from the trail. The following types are found.

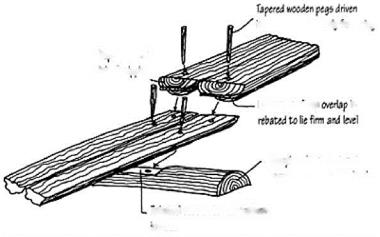

The simplest walks are made from split logs. The two halves are laid flat face upwards, parallel to each other in the direction of the route. The ends and possibly the central point are fixed by nails or pegs to crosspieces, which extend outwards to spread the load and help the walkway to keep afloat. Sections can be joined by overlapping and pegging (see

|

Causeway construction results in a permanent path, and may be the best solution in the most eroded deep peat areas: (a) The peat is excavated and laid to one side. (b) Hard subsoil from beneath the peat is built up into a causeway to ground level. (c) The excavated peat is returned to the ditches cut by excavation of the subsoil. (d) The causeway is surfaced, and drains are left on either side. The result is a firm path that will not settle, sink or erode. |

diagram). These can be made from sections of varying length, which allows the route direction to vary and wind across the area if need be.

Such narrow walkways allow single-file walkers only, and so it is useful if both ends are visible to enable walkers coming in opposite directions to avoid meeting in the middle. Signs might also be needed to advise single-file use, and the need for waterproof footwear where the boardwalk tends to sink into the surface of watery areas. Wider sections for passing can be constructed four planks wide, but these are less easy to keep level because of variable log widths. This method of construction is useful where timber is plentiful because the

ntc Inks et the ow ижп™

ntc Inks et the ow ижп™

Ъ/>Ы e nji redoes

ІЧЇОПЛКІҐ^

ЫсЫс <fl Щ *

ЬШІШ Wiitftner^ s^tuspici sfrssd ttis aac

ЮЯЮ Motion to ЬИ n. tlkft-.iy – і plsto

The method of construction of a split log boardwalk.

|

|

An excellent example of a floating boardwalk laid across bogland. The construction is of sawn timber resting on horizontal cross-bearers to spread the load.

Pacific Rim National Park, British Columbia, Canada.

structures can be made on site from fresh-cut material that is easily replaced. Where rusting metal fixings might be a problem, simple wooden pegs driven through holes will fix the

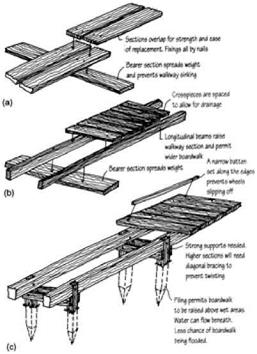

construction satisfactorily. Wider and more sophisticated walkways are needed in other places with more visitors, and particularly for barrier-free access. Parallel beams set 600-900 mm (2-3 ft) apart are bolted to horizontal bearer sections laid on the surface. Planks are nailed to these to provide a walking surface (see diagram). The planks are set wide enough apart for drainage to help keep them dry and free from moss or slime, which might make the surface slippery. Extra grip can be provided by various means such as deck paint, proprietary paints which incorporate a grit, grit stuck to the surface with bitumen, or small-gauge wire netting stapled to the surface. None of these techniques is particularly good either for looks, for convenience or for safety. It is possible to introduce more curves into this type of construction, where the surface pieces overhang the frames and can be cut into sinuous shapes after fabrication.

|

Three methods of boardwalk construction using sawn timber: (a) Flat planks laid on bearers and fixed by nails. (b) A wider structure made by planking nailed to long beams, which in turn are laid on |

cross-bearers. (c) A structure built on piling to lift it above the water or to level out undulating or broken ground.

Where a floating construction is not needed and where the ground is firmer deeper down, posts can be driven in to raise the walkway well above the surface. Construction is similar to the example described above but the beams are fixed to crosspieces bolted to the posts. This might be useful where water levels fluctuate seasonally, and to allow water to move more freely below the structure or to obtain a better view out over the landscape. Wider parts or viewing platforms can be added to the basic boardwalk for fishing or wildlife viewing. Smaller, wider areas can also be provided with benches.

Higher-built boardwalks may require handrails for reassurance and to help less able people to use them. This type is easier to build using shallow ramps to allow wheelchairs to use them comfortably. A narrow rail should be set in from and parallel to the outer edges of the boardwalk to prevent wheels from slipping off. The gap between planks may present an obstruction for small, narrow wheels, especially where turns are needed or on sharp corners if the gap is too wide.

As with all timber used in contact with wet ground, rot will occur unless the timber is naturally durable, such as red cedar, elm or oak, or is treated with preservative. The chemicals used in preservation can be toxic to aquatic life and they should generally be avoided in favour of durable timber. Of the chemicals available, arsenates and creosote should not be used for timber in contact with water; Cuprinol is better, while boron salts are the best, although expensive compared with the others. The subject of preservatives needs more research to look for sustainable solutions. Regular maintenance of timber structures is essential, with prompt repair of broken or weak sections to avoid the risk of injury.

Boardwalks have the added advantage of not disrupting the hydrology of wetland areas in the way that some of the causeway path constructions do.