The material used in this study consists of 2400 Tex E-glass fibres impregnated with an epoxy matrix. The resin is an EPOLAM pre-polymer, EPOLAM 2020 hardener and 2020 accelerator from Axson. Glass fibres are commonly used for naval applications because of their high strength/mass ratio and their low cost compared to other reinforcements. The reinforcement consists of a plain weave fabric with 90% warp yarns and 10% weft yarns. Panels are made by an infusion process and seven orientations are studied: 0°, ±20°, ±30°, ±45°, ±60°, ±70° and 90°. The square panels, 500×500 mm, were cut into cubic samples of the geometry dimensions as shown in Table 1. The standard deviations are indicated in brackets.

|

Panel |

Thickness, (mm) |

Surface (mm2) |

Void fraction (%) |

Stacking sequence |

Fibre volume Fraction (%) |

|

A |

13.00 (0.1) |

13×13 (0.2) |

2.26 |

[0]40 |

53.5 (0.5) |

|

B |

12.52 (0.3) |

13×13 (0.2) |

2.00 |

[±20]20 |

54.0 (0.5) |

|

C |

13.00 (0.1) |

13×13 (0.2) |

1.78 |

[±30]20 |

55.0 (0.5) |

|

D |

12.78 (0.2) |

13×13 (0.2) |

1.69 |

[±45]20 |

54.3 (0.5) |

|

Table 1. Geometry and fibre mass fraction of the samples, standard deviation in brackets |

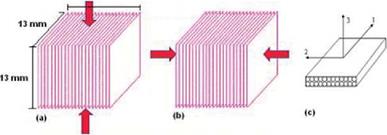

Two types of static compression tests are used to obtain the elastic properties of the lamina. In-plane loading (IP), parallel to the plies plane; plane (1,2), and out-of-plane loading (OP), according to the thickness; direction 3 (Figure 1). Table 2 compares the elastic values of the characteristics drawn from relations of micromechanics (Chamis, 1984) with those resulting from experimental work.

|

Characteristics |

E1 (MPa) |

E2 (MPa) |

E3 (MPa) |

V12 |

V13 |

V 23 |

G12 (MPa) |

G13 (MPa) |

G23 (MPa) |

|

Experimental |

46217 |

16086 |

9062 |

0.28 |

0.41 |

0.097 |

2224 |

3500 |

4540 |

|

Rules law |

42030 |

14524 |

9130 |

0.31 |

– |

0.01 |

3441 |

3273 |

4508 |

|

Table 2. Elastic properties of E-glass/epoxy lamina |

|

1} mm

|

Fig. 1. Sample loadings and coordinates of axis