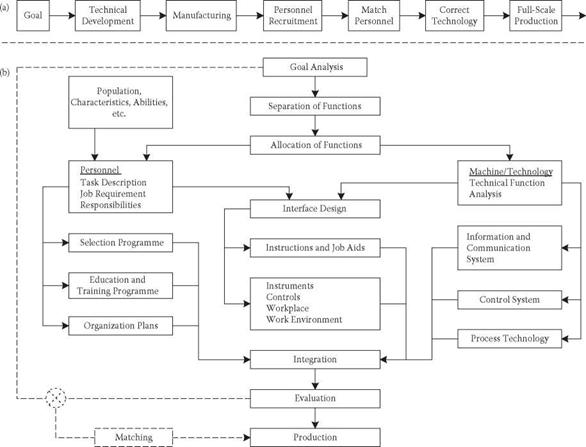

The traditional process is spread over several stages, is ineffective, and often gives poor results (see Figure 13.1b). This construction design is sometimes referred to as the ‘relay race’ model, referring to the stages that are as sequential as the passing of the baton in a relay race. One alternative is the ‘rugby scrum’ approach, where the expert teams collaborate to execute several stages in parallel, as shown in Figure 13.1b. We first present an overview of Figure 13.1b, and then describe each of its subelements in more detail. Figure 13.1b should be regarded first as a philosophy of work; it cannot be treated as a concrete and general work model that can be applied directly to different circumstances.

The goal of a project is defined in accordance with traditional practice and defined in terms that are as concrete as possible. This is followed by a very important element, namely an unprejudiced description of the functions required for the system to fulfil its goal. It is important for the function analysis to be as detailed as possible. It must, however, be phrased partly in abstract terms, because in the next stage decisions will be made in the way in which the various functions will be

|

|

carried out—and whether these are done by a human operator or a machine. The allocation of functions to human or technical components is done in such a way as to fulfil the various criteria regarding health, safety, and comfort. This is a very important element in the planning work, enabling the best possible system to be obtained. The degree of automation in the final system, for example, is determined through allocation of functions in this stage, and the form of technology to be selected is also determined at this point. Allocation of functions indicates which tasks in the system will be done by the human operators, in accordance with the left-hand side of Figure 13.1b. Descriptions of the different tasks involved determine which job and craft skills are required for each one.

Starting with the descriptions of the tasks and job demands, a suitable allocation of tasks is made to the various posts. These in turn will then form the basis for the design of the education and training programmes, organisational plans, instructions, and different types of job aids. In certain cases, and for particular systems, it may also be necessary to have special selection programmes. The technical design work is carried out in parallel. First, the designers decide upon the technology to be used in the process itself, then which control systems are to be used, and how the information and communication systems are to be designed.

At the same time as these two activities are going on, there is close cooperation between the design of the various personnel programmes and the design of the various technical programmes. This collaboration results in the design of the area of contact, or interface, between personnel and technology—that is, the design of instrument and control workplaces (such as work surfaces, tables, and chairs). This work normally uncovers certain unsuitable or incorrect allocations of functions. For example, it may be discovered that functions which are seen to be difficult to carry out or unsuitable have been inappropriately allocated to personnel. These need to be transferred to the technical side, and a technical solution for the functions sought. Alternatively, functions for which it is difficult to find technical solutions may have been allocated to machines. In such cases these are transferred back to the personnel side. In this way, the technical and the personnel sides of the work operations can be worked through and both systems brought together. After this, it may be apparent that there are shortcomings in the degree to which the goals are fulfilled. In such cases, various corrective actions must be made. By following this process, the need for corrections at a later stage will be reduced.

It is important to note that if environmental factors are taken into account from the beginning of the design process, most of the problems normally encountered can be avoided or resolved. This means that the planning must be carried out in accordance with the ‘ergonomic system’ model, shown in Figure 13.1b. Without such a systematic working method, the planning process cannot create a good working environment in the finished system. This model has also proven to be an advanced way to stimulate creativity and thereby discover new innovations and solutions to problems. Allocations of functions fulfil an important role in this process. At the same time, it has also proven to be a useful tool through which to structure and to optimise the balance between human operators and technology.