Printed paper can be encapsulated in a hard-wearing resin to produce a durable and high – quality result. The printing can include photographs, and if an ultraviolet filter is inserted the problems of colour fading in sunlight can be reduced. These resin laminates, when bonded onto a plywood or fibreglass base, are resistant to scratches or chips and can be repaired relatively easily. They are expensive but very durable.

|

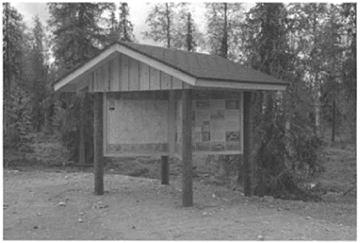

This roofed sign structure from Finnish Lapland has recently been erected, but it repeats the mistakes of older examples. The ponderous roof is top – heavy, casting shade on the information. The siting on the edge of the car park means that one quarter cannot be used. The information is densely printed with large amounts of text, which most people are unlikely to read. The structure was probably quite expensive to construct, but little thought seems to have been given to the quality of information. |

All the sign types described so far can be quite expensive to produce, and many are designed for a long life. If the information is unlikely to change or become out of date they may be the most cost-effective solutions. If the information needs to be changed within two to three years of production it might be sensible to opt for cheaper sign materials of a temporary nature. One version is to laminate paper between two sheets of thick, clear PVC film, heat-sealing the edges. This can be damaged but it is very cheap to replace the whole thing, attaching it to a baseboard in such a way that it can be easily removed.