In the case of knitted fabrics, the 3D architecture is facilitated by their high extensibility and formability that allow the production of complex shapes. This is the reason why the knitted fabrics are regarded as a viable option for preforms for advanced composite materials.

The main advantages of the 3D knitted fabrics are:

a. the high formability of the fabrics, especially due to their drape characteristics

b. the high complexity of the shapes that can be produced;

c. the use of existing technology, without major adaptations;

d. knitted fabrics exhibit good impact behaviour.

Knitted three dimensional performs are less studied and used, mostly because the following problems related to their production and their properties:

a. the development of these fabrics is still at laboratory stage;

b. the mechanical characteristics of the resulting composites are at a lower level and require improvement;

c. the specific properties and their prediction are not yet well developed, mainly because of the complexity of the knitted fabrics;

d. the pretension of the perform before its impregnation with resin determines a uneven behaviour for the final composite due to fibre migration in the stitches.

The 3D knitted fabrics can be divided into three main groups: multiaxial fabrics (multilayer), sandwich/spacer fabrics and knitted fabrics with spatial geometry (spatial fashioned).

Multiaxial fabrics

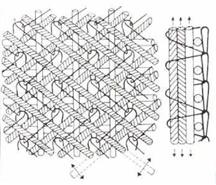

The multiaxial fabrics are characterised by the presence of multiple layers of yarns disposed at preferential angles that are assembled in the knitted fabrics. These fabrics are produced on special warp knitting machines using glass fibre or carbon fibre for the layers. The warp knitting technology is best suited for this kind of structures with in-laid yarns. Multiaxial fabrics are used mostly for the reinforcement of composite materials.

|

|

Fig. 10. Structure of the multiaxial knitted fabrics

The different layers of yarns in the multiaxial warp knitted fabrics are independent and the yarns fed under preset angles: 00 (weft yarns), 900 (warp yarns) and any value between these, like +/- 300 and +/- 450. The layers are united by the actual knitted fabric, using pillar or tricot stitches, as exemplified in Fig. 10 (Raz, 1989).

The preset angles correspond to the directions requiring higher strength during use and are imposed by the application. Currently, there are two main technologies adapted for the production of multiaxial fabrics: the Karl Mayer technology and the Liba technology.