|

The application presented in the paper refers to a knitted preform for an airplane wing (glider). It was intended to knit a 3D shape identical to the wing. The preform was used to produce the composite material (through RTM). |

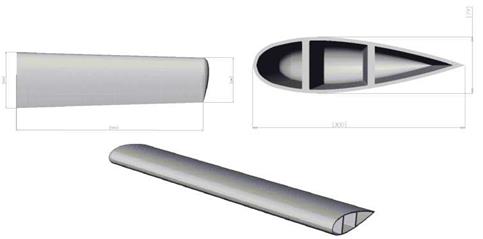

Type and geometry of the knitted preform

The airplane wing prototype was defined using NACA 4 digital profile, according to specifications. Fig. 32 presents the geometry and dimensions of the chosen profile.

The wing is characterised by the following aspects:

• A difference in width between the beginning and the end of the wing – that requires successive narrowing;

• The difference between the two extremities is 60 mm, determining the narrowing slope;

• The fabric thickness for the outer layer is 5 mm;

• There are two interior walls with 5 mm thickness and different heights, according to the wing cross section: 79 mm – for the higher wall, and 64 mm – for the smaller wall.

|

|