1.1 Fiber-dominant strength, matrix-dominant strength, and failure modes

As described above, static tensile strength and tension fatigue strength are predominantly fiber-dominant, and static compressive strength and compression and tension-compression fatigue strengths are matrix-dominant. This section discusses the fiber-dominant and matrix-dominant characteristics of static and fatigue strengths based on observations of specimen failure and failure modes. The mechanical properties of carbon fibers are considered to be constant over the range from RT to 215°C. Moreover, since no signs of fatigue damage were found in the fibers themselves, any fatigue strength reduction of carbon fibers can be left out of consideration. Therefore, matrix damage influenced by temperature and load repetition is considered to generate the temperature dependence of the static and fatigue strengths, and also the load cycle dependence of fatigue strength. Initially, we will consider static NHT strength. In order to generate tensile failure in an NH specimen, fibers in the 0° fiber layers that directly bridge both end regions where the load is

introduced must finally be broken. If static tensile strength is determined only by 0° fiber fracture, temperature dependence will not appear and perfect fiber dominance will be seen. However, both the static NHT and OHT strengths in Fig. 2 indicate small temperature dependence. This means that the matrix has a small effect on static tensile strength. This aspect can be clarified by examining the failure mode of a specimen. The load-displacement diagram observed in a static tensile test of an NH specimen was considered to be linear up to final failure. In addition, fibers in the 45° fiber layers did not bridge both ends where the load was introduced. Thus geometry tells us that if 45° fiber layers also share internal load via the matrix until the fracture of 0° fiber layers, the final strength of the laminate will become higher than if only 0° fiber layers share internal load. This phenomenon can be evaluated by inspecting whether fiber fracture exists in the 45° layers after final specimen failure.

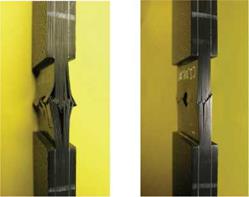

Fig. 7 shows surface and side views of static tensile failure in NH and OH specimens. A surface view of static tensile fracture in an NH specimen at RT is shown in Fig. 7(a). The front line of the surface 45°-fiber-layer fracture intersects with the 45° fiber direction at 90°. In addition, the 45° fiber layer was also cut at the load-axis orientation. This is evidence that the ±45° fiber layers shared the axial load via the matrix until just before the final specimen fracture. Since the fiber binding strength of the matrix will decrease with increasing temperature, the load sharing rate of the ±45° fiber layers will decrease at the same time. Fig. 7(b) shows the static tensile fracture of an OH specimen at RT, with surface and side views from the same specimen. As shown in the left-hand figure, only a small number of surface +45° fibers failed. The right-hand figure displays small slits in a comb pattern produced by fiber separation in the -45° fiber layers in the upper part of the side face. Such slits extended even to the lower part of the opposite face. In the lower part of the slits in the right-hand figure, delaminations produced by the pull-out of 0° fibers can be seen. These facts mean that +45° fibers fractured inside the specimen. Static OHT strength dropped slightly with increasing temperature similarly to static NHT strength, as shown in Fig. 3. However, the matrix binding strength decreases at elevated temperatures in comparison with that at RT, and stress concentration around the open hole is considered to drop at elevated temperatures. Therefore, this is a possible reason why OHT strength has small temperature dependence but does not fall in the same way as NHT strength at 150°C.

Next, we consider static compressive failure. The compressive strength of a composite material is considered to reflect the temperature dependence of the matrix strength. Fig. 8 shows the appearance of static NHC failure, which formed a rhombus shape in the side view. The main failure mechanism is considered to be compressive buckling failure generated by delamination progressing from micro-buckling. Partial shear fracture in the side view is also confirmed. This macroscopic shear fracture can be considered to have progressed from kinking initiation. Since these mechanisms of compression failure initiation depend on matrix strength (Pilato & Michno, 1994), the compressive strength is directly related to the temperature-dependent matrix strength. Fig. 9(a) and (b) show side views of static compression failure of different OH specimens at 150°C. Around the cross section having an open hole, macroscopic rhombus-shaped failure and shear failure in the thickness direction can be seen. Figure 9(a) shows typical rhombus-shape failure and the fracture mode in Fig. 9(b) seems to be shear-dominant; however, the fracture mode around the hole has a rhombus shape. Though the compressive fracture mechanism in an OH specimen is similar to that in an NH specimen, the drop of compressive strength at 150°C from RT is smaller than that of an NH specimen. This phenomenon is considered to originate in the relaxation of stress concentration around the hole at 150°C.

|

|

In the case of tension fatigue, matrix damage such as transverse micro-cracking and small delamination occurs in the open-hole wall and grows with the increase in the number of load cycles, and the 0° fiber layers gradually charge themselves with the load that ±45° fiber layers shared. Specimen failure will occur when the 0° fiber layers are loaded up to the limit load or the limit strain to failure. This means that although fatigue strength is influenced by high temperature and load repetition, there is a compensating effect as high temperature and load repetition reduce stress concentration around the open hole. Therefore, the tension fatigue strength is strongly fiber-dominant; however, it is slightly influenced by high temperature and the number of load cycles.

|

Fig. 7. Surface and side views of static tensile failure of NH and OH specimens

In the case of compression fatigue, fatigue damage such as transverse micro-cracking and small delamination occurs in the open-hole wall and delamination and local buckling progress, finally resulting in compression buckling failure. Inspection also showed partial shear fracture in the thickness direction. Thus, compression fatigue strength is governed by matrix failure and dependent on temperature and the number of load cycles. Additionally, the relaxation effect of stress concentration around the hole on compression fatigue strength is superimposed, producing the S-N relationships shown in Fig. 5. Rosenfeld and Gause also

pointed out that compression fatigue strength is matrix-dominated for a CF/epoxy composite material (Rosenfeld & Gause, 1981).

|

(a) OH specimen, 150°C (b) OH specimen, 150°C Fig. 9. Side views of static compressive failure of OH specimens |

In tension-compression fatigue, the final failure mode was similar to that of compression fatigue, i. e. delamination buckling. This fact suggests the important role of compression load repetition promoting delamination growth. The tension load component is also thought to contribute to delamination buckling by accelerating the initiation and growth of matrix damage. That is, the fatigue failure mode in tension-compression fatigue can be considered to be matrix-dominant and the tension-compression fatigue strength is dependent on temperature and the number of load cycles.

As mentioned above, since static compressive strength, compression fatigue strength, and tension-compression fatigue strength can be classified as matrix-dominant properties, the effectiveness of using a high-temperature resin as a matrix in an elevated temperature environment can be established. This viewpoint is very important and discussed again later.