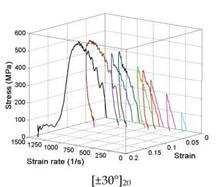

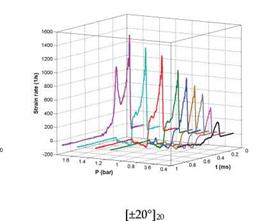

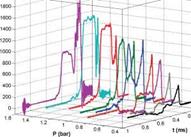

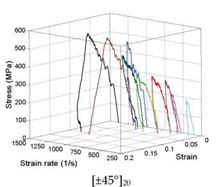

For out-of-plane (OP) tests, figure 8 give the evolution of the strain rate of [0°]40, [±20°]20, [±30°]20 and [±45°]20 samples for 9 impact pressures. The appearance of a second peak is around 0.9bar for [0°]40 and 1.4bar for the other orientation, Table 4. The dynamic behaviour is dominated by compressive properties of the polymeric matrix and the damage is created for high impact pressure. The fibres orientation affects the initiation and propagation of damage. For undamaging tests, the fall of strain rate passes by negative values, which correspond to the springback in the sample. The glass/epoxy composite materials present a high strength on compressive dynamic loading for OP tests.

[0°]4

|

1600

1600

1400

1200

1000-

[±30°]20

Fig. 9. Strain rate evolution versus impact pressure

|

OP Tests |

[0°]40 |

[±20°]20 |

[±30°]20 |

[±45°]20 |

|

Pc (bar) |

0.9 |

1.6 |

1.6 |

1.4 |

|

Table 4. Critical impact pressure for appearance of second peak |

![]()

|

|

|

|

|

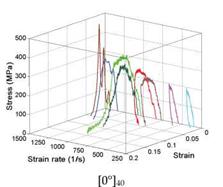

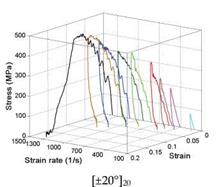

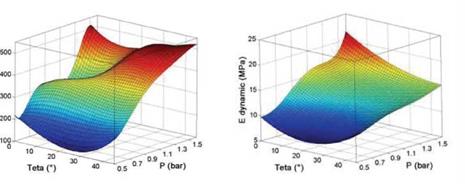

(a) Maximum stress

One can note that [20/70] and [30/60] have similar dynamic response, Figure 10. The unloading part of a = f (є) curves indicates if there is plasticity or other damaging modes. The second peak of є = f (t) curves corresponds to the fall of stress in the sample. The dynamic behaviour of the various laminates is strongly affected by the strain rate and fibres orientation, Figure 11. For OP tests, there is always an increase in E, . and a with the

increase in the impact pressure. There is not threshold effect for OP loading; the transitional pressure does not exist.