Using the once studied properties of the composite, the software of CMS allows multiple to simulate the curing process on the computer under different conditions, thus calculate the temperature-conversion field during curing of composite, as well as represent them in the form of graphs and 3D surfaces, thereby, to analyze the uneven curing of the material for the manufacture, quickly assess the advantages and disadvantages of the used curing cycle for the material and choose the right strategy to optimize the cycle.

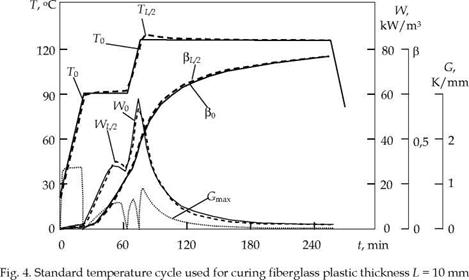

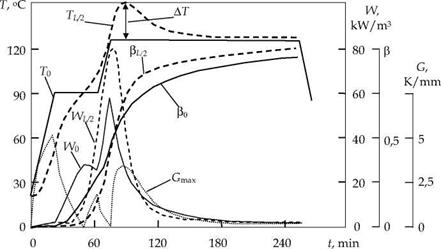

Similar numerical studies were performed on a computer for fiberglass plastic and made a numerical analysis of the existing standard cure cycles, designed for the production of plates with thickness up to 10 mm, we evaluated their suitability for the production of thicker plates, for example 30 mm thick, and we calculated the optimal curing cycles. The temperature-conversion field, ie the temperature at the surface of the plate T0 and in the middle TL/2, respectively, the degree of curing p, the rate of evolved heat of cure reaction W and the maximum module temperature gradient G on the thickness L in the process of curing fiberglass plastic on the two-step cycle thickness L = 10 and 30 mm are shown in Fig. 4-5.

Based on the analysis of numerical calculations of temperature-conversion fields (Fig. 4-5) can do the following conclusions:

1. In general, the standard cycle is suitable for the manufacture of plates with thickness up to 10 mm. Here there are small temperature gradients G, and drops in temperature T0-TL/2=AT, that is overheating of the inner layers due to the exothermic effect.

|

|

|

Fig. 5. Standard temperature cycle used for curing fiberglass plastic thickness L = 30 mm |

2. When curing the material thickness L = 30 mm at the standard cycle in the first step the temperature drops are AT1=12,0 K, the temperature gradients are Gi = 1,52 K/mm, in the second step, when there is formation of the structure of the material the maximum overheating AT2 and the maximum module temperature gradient G2 reach respectively AT2 = 25,i K, G2 = 2,59 K/mm. With such a temperature drop over the thickness and overheating of the inner layers of the material begin to occur the destruction processes of the resin, increasing the porosity of the composite, residual stresses accumulate. All

this causes a decrease in the strength properties of the material, and in the manufacture of large-sized products appears to warping. Also, be aware that the large structures made of composite materials, such as elements of the wing, tail and fuselage are structures with different thickness, so the flow of polymerization processes in these zones of the composite are significantly different. In this case, the molding cycle should be chosen so as to obtain the necessary strength characteristics in most of the large area of intense construction.

These results demonstrate that the use of temperature-time curing cycle, as defined in laboratory conditions and is recommended for thin samples can not be used in the curing product of a thickness exceeding 10 mm. In these cases, to obtain high quality products require regular technical correction cycle, or its optimization.