Currently optical fibre sensors (OFS) are increasingly widely used to monitor the mechanical properties of composite materials and structures in their operating conditions where the reliability and safety of the structures (often working under extreme strains) is critical. Typical applications of various OFS to condition monitoring are presented below. Strain (displacement) and temperature are the main parameters which can be measured by such techniques. On the basis of the measured strain and temperature one can estimate other mechanical parameters, such as stress/strain distribution, force, pressure, curvature, leakage and so on.

1.1 Fibre bragg gratings

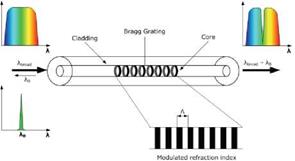

Fibre Bragg gratings (FBG) are the most popular fibre based sensors. A Bragg grating is a structure made inside the core of a single-mode optical fibre, characterized by periodical changes in the value of the refractive index (Fig. 1). Due to the presence of such a modulated

|

Fig. 1. Scheme of fibre Bragg grating principle of operation |

structure inside the core of the optical fibre some of the optical radiation transmitted through the latter is reflected from the grating structure while the remainder is propagated without any loss (Yu & Yin, 2002). The wavelength reflected from the Bragg grating, the so – called Bragg wave (XB), is described by the relation:

where: ruff – the effective refractive index of the optical fibre core, Л – a Bragg grating constant.

Sensors bonded to the external surface of the monitored structure or located inside the material are subject to deformations causing changes in the Bragg wavelength, which becomes the touchstone for the measured deformations. It should be noted, however, that a change in AB in real measuring systems is the result of the simultaneous influence of temperature and deformations, which can be measured in ranges: -270°C + 800°C and -3% + 3%, respectively.