SMART magnetic materials (SMM) are active materials which in recent years have been increasingly often and wider used in the aerospace industry, the navy, the car industry, civil engineering and in many other fields (Schwartz, 2002). The so-called giant magnetostrictive materials (GMMs) form a major subgroup in SMM. They enable the conversion of magnetic energy into mechanical energy and vice versa with high efficiency. A typical representative of GMMs is Terfenol-D which offers many advantages but its low tensile strength and the occurrence of high eddy currents detract from them. Attempts are made to eliminate the drawbacks by creating composites. For several years now research projects, e. g. (Kaleta et al., 2009; G^sior et al., 2009; Yin Lo et al., 2006), targeted at creating magnetostrictive materials capable of assuming the form of, e. g., rods or laminates and effectively replacing solid Terfenol-D, have been conducted. Such composites offer the possibility of new applications, in e. g. SHM (tagging).

b)

|

|

Monolithic (solid) GMMs and composites incorporating them are tested mainly with regard to their magnetic properties. The parameters describing these properties are magnetostriction (the deformation of a ferromagnetic under the influence of an external magnetic field) or the opposite effect (the Villary effect). In both cases, the conventional methods of measuring strains (e. g. by means of extensometers or strain gauges) are practically inapplicable since GMMs are inside coils (or even constitute their core) and the sharp fluctuations in E-M fields there disturb the measurement.

For this reason, optical fibre sensors are an ideal solution for measuring the mechanical parameters of magnetic materials (including GMMs). Owing to their dielectric nature they are resistant to all electromagnetic interferences and in addition, enable strain registration with an accuracy as high as 1 pe.

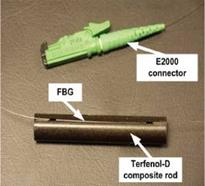

In (Kaleta et al., 2009; G^sior et al., 2009) the authors used FBG sensors to measure the deformation of solid Terfenol-D rods and composite rods based on epoxy resin and powdered Terfenol-D. The fibre-optic sensors were installed on the surface of the samples (Fig. 7a) in the longitudinal and circumferential directions whereby magnetostriction could be measured in two directions. During the bonding of the sensors to the samples the latter were prestressed. As a result, strains could be measured under both compression and tension. This is important since in order to obtain optimum operating conditions for these composites they need to be prestressed (Kaleta et al., 2009).

The aim of the static tests described in the above papers was to determine the magnetomechanical properties of rods made of GMM composites and solid Terfenol-D. Their magnetostriction was determined depending on the percentage of the magnetic phase in the material (Fig. 7b). The test results showed that although the magnetostriction is three times lower in comparison with that of the solid material, it is about 30 times higher than that of nickel (the reference material). But the influence of eddy currents was eliminated and the tensile strength increased (Kaleta et al., 2009).