|

|

The squeeze casting is likely one of the most usual manufacturing processes for elaboration of metal matrix composites (MMC). This process consists in the production of rigid porous structures with reinforcement, in our cases carbon fibre structure, that are further infiltrated by metal molten under pressure (fig. 8). The molten copper is poured (1180°C) into the bottom half of the pre-heated die (close to 1000°C).

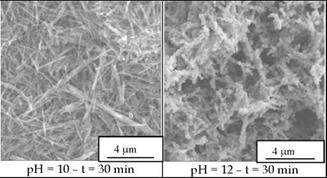

Fig. 6. Evolution of the coating behaviour with the pH of the solution

![]()

|

|||

4 pm

4 pm

d) ![]() 100 ml of water

100 ml of water

|

Fig. 7. Evolution of the coating behaviour with the water concentration

During the infiltration step, the carbon fibre structure is placed in the die. The main inconvenient of this technique is to keep steady the metal liquid during the infiltration step

because of the high melting point of copper (1083°C). Other inconvenient is linked to low wettability of copper with carbon, which involves the high infiltration pressure. This low wettability can lead to carbon fibre agglomerates and the presence of micro porosity in composites. Then, the squeeze casting is not the best process route for the elaboration of Cu/C composites.