The experimental results were calculated based on the raw data from the testing machine, according to the established methodology (ASTM D 2256), to obtain the following values: breaking strength, breaking tenacity, Young’s modulus E, breaking elongation, breaking toughness and time to break. The results are centralised in Table 5. Yarn variant called Normal is the witness yarn, while the other variants are yarns knitted with a certain position for the stitch quality cam, defined in Table 3.

|

Yarn count [tex] |

Yarn variant |

Breaking force [N] |

Breaking tenacity [cN/tex] |

E modulus [N/tex] |

Breaking elongation [%] |

Breaking toughness [J/g] |

Time to break [sec] |

|

136 |

Normal |

75.67 |

55.59 |

27.37 |

2.2 |

6.64 |

6.89 |

|

NP 3 |

23.59 |

17.27 |

14.79 |

1.38 |

1.45 |

4.14 |

|

|

NP 4 |

30.92 |

22.73 |

18.26 |

1.42 |

1.93 |

4.24 |

|

|

NP 5 |

37.51 |

27.58 |

21.24 |

1.55 |

2.47 |

4.66 |

|

|

408 |

Normal |

229.87 |

56.34 |

84.65 |

2.46 |

6.86 |

6.76 |

|

NP 2 |

118.73 |

29.10 |

61.18 |

1.87 |

3,01 |

5.60 |

|

|

NP 3 |

156.59 |

38.37 |

69.52 |

2.00 |

4.29 |

6.01 |

|

|

NP 4 |

165.05 |

40.45 |

70.08 |

2.12 |

4.86 |

6.38 |

|

|

NP 5 |

167.83 |

41.14 |

71.66 |

2.15 |

4.87 |

6.44 |

Table 5. Experimental results for tensile testing

Discussions

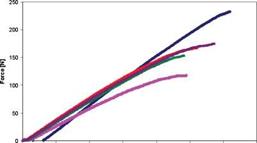

Contrary to Law and Dias, the experience of knitting on flat electronic machines showed that the needle could be pulled inside its channel without restrictions for the lowest point. The relation filament breaking – stitch length was found to be opposite to the one presented by Law and Dias. For each yarn count there is an inferior limit for the stitch length, guaranteeing the quality of the fabric. For this limit the degree of filament breaking is so high the yarn is almost completely destroyed and will break when unravelled from the fabric. It is the case of the 136 tex yarn knitted with NP2 stitch cam position. No tensile tests were performed for this variant and therefore it was not included in the experimental data. The differences in strength and tenacity, compared to the normal values, show that the knitting process has a negative influence on the tensile properties. Furthermore, the decrease in strength is in a direct correlation with the stitch length – the lower the stitch length, the lower the tensile properties. Figs. 7 and 8 present the representative graphics for each type of yarns, illustrating the variation of the breaking force with the elongation.

|

136tex

0 1 2 3 4 5 6 7 Elongation [mm] ♦ Normal NP3 NP4 ж NP5 Fig. 7. Force-elongation curves for the EC 13 136 Z30 P 100 glass yarn |

|

408 tex

0 1 2 3 4 5 6 7 Elongation [mm] ♦ Normal ■ NP2 NP3 NP4 NP5 |

The experimental data and the graphics are showing a contradiction with Law and Dias, concerning the cause of filament breakage during knitting. If the tension occurring in the looping point is responsible for the filament damage, then higher stitch length should present higher values for the breaking force, but the experimental results contradict this. One answer for this different opinion could be the feeding mechanism. In this case, the yarn was fed using an IRO NOVA feeding device, ensuring the proper quantity of yarn for the process. Without it, knitting proved impossible.

The breaking phenomenon appears due to the friction between the yarns and the knitting elements, especially the knock-over plates that can act like knifes during rob back stage. The longer the stitch length, the smaller the tension in yarns and there is less filament damage. The differences between the normal values and the ones for the knitted yarns 136 tex are varying from – 71% in case of the smallest stitch length and – 55% for the highest stitch length. In the case the 408 tex yarn, the difference interval is – 48.34% to – 26.99%.

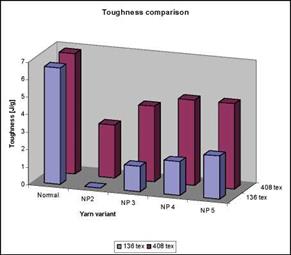

The decrease in breaking toughness is more significant, as illustrated in Fig. 9. The toughness value for the 136 tex NP2 variant was introduced and was considered 0 only for comparison purposes. When compared, the initial toughness values for the two yarns are similar, but the 136 tex yarn shows a much higher decrease in breaking toughness then the other yarn. The decrease interval for 136 tex is extremely high 78-63%, while for 408 tex the decrease is in the interval 56-29%.

|

Fig. 9. Influence of yarn count and filament damage on breaking toughness |

This situation suggests the influence of the number of filaments in the yarn, and also the fact that the amount of filament damage on the knitting machine is the same, regardless of the yarn count. A superior number of filaments ensure a better knittability, the yarn maintaining better tensile properties.

The breaking force and toughness values determined for the yarns knitted with NP4 and NP5 stitch cam positions are similar indicating that filament damage amount is the same. Even if the best properties are obtained for the highest stitch length – corresponding to NP5 value for the quality cams, this must be balanced with the fabric density, essential for the

overall performance of the fabric in the composite material. Therefore, the optimum technological parameters appear to be those for the fourth situation, with NP4 value for the stitch quality cam. In practice, even if the strength level is lower, value NP3 can also be used, due to the higher fabric density.