Industrial estates are gaining popularity in parts of Europe, but they take more planning and coordination than simply redesigning and building a factory. Consider the energy required to extract, smelt, cure, and refine ore into steel. Once poured into ingots, this steel is then cooled, transported to another supplier (often across vast distances), heated again to be formed into a new shape, cooled, shipped, heated, formed, cooled, and so on, repeating the process many times. Each time the steel is heated and cooled, a lot of energy is used and wasted. This is the case for many materials, including other metals, glass and ceramics, plastics, and so on.

Now consider a series of factories co-located so that the order can be heated and processed, and then moved to a final mold in one step, without cooling and reheating several times and without interim forms. Consider how co-located factories could quickly and easily move and transform wastes from one process into inputs for another. This is what an industrial estate (also known as industrial symbiosis or industrial ecology) is designed to enable. When designed, built, and run correctly, an industrial estate can realize enormous efficiencies over standard systems, while increasing recycled content (at least on the industrial side) and decreasing dissemination of toxic or undesired substances (since they’re more localized, they’re easier to manage). These are perfect solutions, but they require tighter and tighter closed-loop systems.

In his book, The Performance Economy, Stahel describes these loops in larger terms, adding financial and human capital to this model, and comparing them to traditional solutions. He contrasts the “River Economy,” where materials, goods, services, and profits run through a community without leaving lasting benefit (especially economic benefit), to the “Lake Economy,” where these materials pool in communities for greater local benefit.

Lake economics allow communities to retain capital in all its forms and amplify them in the form of interest, jobs, and assets. Lake economies benefit from closed-loop thinking and must deal with both the products and wastes of systems. In essence, it’s in the community’s interest to manage and value the entire life cycle and the rewards and responsibilities that come throughout.

Closed-loop systems offer opportunities for new companies to create new solutions and services that reclaim value in previously discarded (or buried) materials and previously unlinked flows of information material, energy, and services.

Not everything, however, can be made in a lake economy. Sophisticated products and services that require rare materials or expertise can’t be distributed everywhere. It’s not likely that iPhones will be sourced, manufactured,

sold, used, reclaimed, and recycled in thousands of towns across the U. S. Nor is it likely that every kind of fruit can be grown everywhere in every climate, or that every hospital will have experts in every treatment on staff. Regional differences in knowledge, materials, resources, and climate will always create the need for interlinked economies. However, the effects of small towns being drained of financial and other resources due to multinational corporations that move these resources, over time, to their headquarters can be countered through more thoughtful implementations of services in a lake-type economy.

Closed loop systems offer opportunities for new companies to create new solutions and services that reclaim value in previously discarded (or buried) materials and previously unlinked flows of information, material, energy, and services. Informationalization and transmaterialization (described in previous chapters) are two strategies that can enhance closed-loop systems and lake economies. Likewise, all of the frameworks described in Chapter з can be employed to identify opportunities to enhance efficiencies and find value where none exists today.

Kalundborg, Denmark

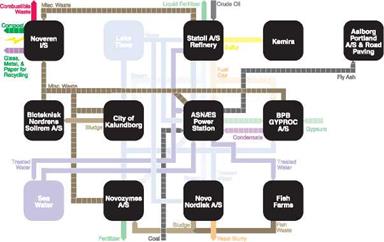

On the west coast of Denmark’s Zealand Island is a town known as the best example of an industrial estate, Kalundborg, Denmark. Though first settled in the 1100s, in the beginning of the 1960s, a long, slow process of cooperation between the town government and businesses began with a pipeline to supply fresh water to a new refinery. Now, five core partners and many smaller companies interchange resources, material waste, and energy in an efficient web that has created over $i2oM in savings on investments of $6oM (see Figure 13.2).

For example, the Statoil refinery consumes water from a nearby lake, crude oil, and excess steam from the Asnaes power station and outputs water and fuel gas to the power station, as well as sulfur (cleaned from emissions) to a

|

FIGURE 13.2. http://www. flickr. com/photos/rosenfeldmedia/3264829427 The Kalundborg Industrial Estate coordinates inputs and outputs from many area organizations in order to use energy, materials, and waste efficiently. |

company that creates sulfuric acid. The power station consumes coal and water (partly from the refinery) and outputs steam to heat homes in the city and to Novo Nordisk, a pharmaceutical factory responsible for 40 percent of the company’s production of insulin, gypsum to Gyproc, a manufacturer of plasterboard, and fly ash to Aalborg Portland for paving roads.

Kalundborg, Denmark (continued)

There are other benefits as well (this is only a sample,) and while this model evolved naturally (it was not planned from the beginning but self-organized over time), there’s no reason but lack of imagination and the will to act that prevents other communities from reaping even more benefits by planning industrial estates for themselves.

www. symbiosis. dk

William Good

In 2007, Goodwill Industries of San Francisco, San Mateo and Marin counties partnered with Nicholas Graham, founder of Joe Boxer, to create and launch a new business remanufacturing haute couture outfits from clothes donated to Goodwill (see Figure 13.3). The purpose of this new company was to choose clothes and materials from the massive amounts regularly donated and have designers make original pieces worthy of an expensive boutique.

One of the reasons Goodwill is entering this market is that it simply has way too many clothes in its warehouses for the amount of demand available in their current stores. By crafting an offering for a different market, they hope to expand their ability to recycle, reuse, and resell the material donated to them, as well as train and employ people to give them usable skills for the future (their primary mission).

4?

4?

william good

remnde пі ■.!)£ USA

LEFT IMAGE:

/W http://www. flickr. com/photos/ rosenfeldmedia/3272496923

right image:

/W http://www. flickr. com/photos/ rosenfeldmedia/3338282624/

FIGURE 13.3.

William Good’s re-creations are fun, stylish, and often surprising.

The William Good brand, and similar ones for other categories of donated goods, helps the organization close the loop between disposal and manufacturing. By taking in items customers are finished with, Goodwill creates a direct link for them to go back to manufacturing and new use.

www. shopwilliamgood. com

CHAPTER 14