Bending wood is traditionally achieved through a process of steaming wood in a contained chamber. After the cells have been saturated with moisture, enabling the wood to flex, the wood is then bent to shape or pressed into shape using a two-piece form. Samuel Gragg (1772-1855) made a series of furnishing using this process. He received his "elastic chair" patent on August 31, 1808, and used steam to bend structural parts of his furniture, as evident in the bent slats and seat of the chair shown in Figure 8.7. The profile of the chair is similar to the profile of the Greek Klismos chair.

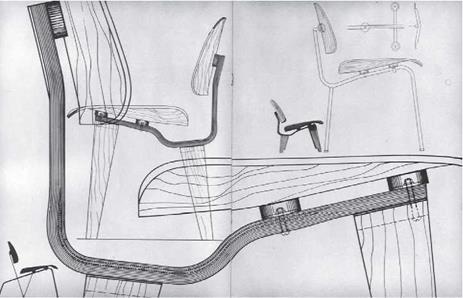

Bending plies of wood is an effective way to make curved forms with less waste. Beech or birch veneers are commonly used for this process. Thin veneers of these woods are layered with glue and pressed together around a metal form or compressed using a mold with heat and/or ultrasonic vibration (Figure 8.8). When taken out of the mold, the

shaped form is sent to a trimmer. The result is high manufacturability, cost-effective fabrication (the initial tooling cost is relatively high, however), light weight, and a sturdy design, as shown in the laminated and molded plywood chairs by Charles and Ray Eames (Figure 8.9).

|

Figure 8.9 Collage of drawings at different scales, with side views of Eames’s laminated plywood chairs. Photography by Charles Eames. Courtesy of Herman Miller, Inc. |

|

Figure 8.10 Hand-carved detail in walnut. Courtesy of Cincinnati Art Museum, Gift of Melrose Pitman. Accession No. 1970.81. |

CARVING

Carving is an ancient art and a contemporary science, depending on whether it was done by hand or by machine. When it is done by hand, it is a craft in the true sense of the word. Woodworkers use chisels and gouges to carve and work wood (Figure 8.10).

Many designers and industries use computer numeric controlled (CNC) devices to carve various materials for making furniture. Stone, polymers, and wood products can be milled

by CNC devices using digital programs and computer hardware. The most intricate patterns are possible, and the cost of the work is a fraction of the cost of doing the work by hand (Figure 8.11).