Formal methods for LCA first emerged in a series of meetings organized by the Society for Environmental Toxicology and Chemistry (SETAC), of which the most significant were held in 1991 and 1993. This led, from 1997 on, to a set of standards for conducting an LCA, issued by the International Standards Organization (ISO 14040 and its subsections 14041, 14042, and 14043). These prescribe procedures for "defining goal and scope of the assessment, compiling an inventory of relevant inputs and outputs of a product system; evaluating the potential impacts associated with those inputs and outputs; interpreting the results of the inventory analysis and impact assessment phases in relation to the objectives of the study." The study must (according to the ISO standards) examine energy and material flows in raw material acquisition, processing and manufacture, distribution and storage (transport, refrigeration, and so forth), use, maintenance and repair, recycling options, and waste management. There is a lot here and there is more to come. A summary in plainer English might help:

■ Goals and scope. Why do the assessment? What is the subject, and which bit(s) of its life are assessed?

■ Inventory compilation. What resources are consumed, what emissions excreted?

■ Impact assessment. What do these do to the environment— particularly, what bad things do they do?

■ Interpretation. What do the results mean and what is to be done about them?

We look now at what each of these questions involves.

Goals and scope. Why do the study? To what purpose? And where does such a study begin and end? Figure 3.2 shows the four phases of life, each seen as a self-contained unit, with notional "gates," marked as ®, through which inputs pass and outputs emerge. If you were the manager of the manufacturing unit, as an example, your goal might be to compile an assessment of your plant, ignoring the other three phases of life because they are beyond your control. This is known as a gate-to-gate study, the scope limited to the activity inside the box labelled System Boundary A. There is a tendency for the individual life phases to minimize energy use, material waste, and internalized emission costs spontaneously because it saves money to do so. But this action by one phase may have the result of raising resource consumption and emissions of the others. For example, if minimizing

the manufacturing energy and material costs for a car results in a heavier vehicle and one harder to disassemble at end of life, the gains made in one phase have caused losses in the other two. Put briefly: the individual life phases tend to be self-optimizing; the system as a whole does not. We return to this topic in Chapters 8 and 9, where the necessary trade-off methods are developed.

If the broader goal is to assess the resource consumption and emissions of the product over its entire life, the boundary must enclose all four phases (System Boundary B). The scope becomes that of product birth to product death, including, at birth, the ores and feedstock that are drawn from the Earth’s resources and, at death, the consequences of disposal.

Some LCA proponents see a still more ambitious goal and grander scope (System Boundary C). If ores and feedstock are included (as they are within System Boundary B), why not the energy and material flows required to make the equipment used to mine or resource them? And what about the flows to make the equipment that made them? Here an injection of common sense is needed. Setting the boundaries at infinity gets us nowhere. Equipment-making facilities make equipment for other purposes too, and this gives a dilution effect: the more remote they are, the smaller the fraction of their resources and emissions that is directly linked to the product being assessed. The

standards are vague on how to deal with this point, merely instructing that the system boundary "shall be determined," leaving the scope of the assessment as a subjective decision. A practical way forward is to include only the primary flows directly entering the materials, manufacture use, and disposal of the product, excluding the secondary ones required to make the primary possible. We shall follow this route in the audits of Chapter 7.

Inventory compilation. Setting the boundaries is the first step. The second is data collection: amassing an inventory of the resource flows passing into the system and the emissions passing out, per unit of useful output. But how is this data to be measured? Per kilogram of final product? Yes, if the product is sold and used by weight. Per m3 of final product? Yes, if it is sold by volume. But few products are sold and used in this way. More usually it is neither of these, but per unit of function, a point we will return to in later chapters. The function of a container for a soft drink (a soda bottle, a plastic water bottle, a beer can) is to contain fluid. The bottle maker might measure resource flows per bottle, but if it is concerned with environmental or economic consequences of its entire life, it is the eco-impact or cost per unit volume of fluid contained that is the proper measure. Refrigerators provide a cooled environment and maintain it over time. The maker might measure flows per fridge, but the logical measure from a life-cycle standpoint is the resource consumption per unit of cooled volume per unit time (cold m3/year, for instance).

We will find that the functional unit of a resource entering one phase is not the same as those leaving it. There is nothing subtle about this, it’s just to make accounting easier. Thus the flow of materials leaving Phase 1 of life and entering Phase 2 are traded by weight, so the functional unit here is per unit weight: the embodied energy of copper, for instance, is listed in the data sheet as 68-74 MJ/kg. The output of manufacture is a component or product; here kilograms or product units may be used. It is in the use phase that the function becomes important and here the real measure—that per unit of function—becomes the logical one.

The inventory analysis, then, assesses resource consumption and emissions per functional unit. It is also necessary to decide on the level of detail—the granularity—of the assessment. It doesn’t make sense to include every nut, bolt, and rivet. But where should the cut-off come? One proposal is to include the components that make up 95% of the weight of the product, but this is risky; electronics, for instance, don’t weigh much, but the resources and emissions associated with their manufacture can be large, a point we return to in Chapter 6.

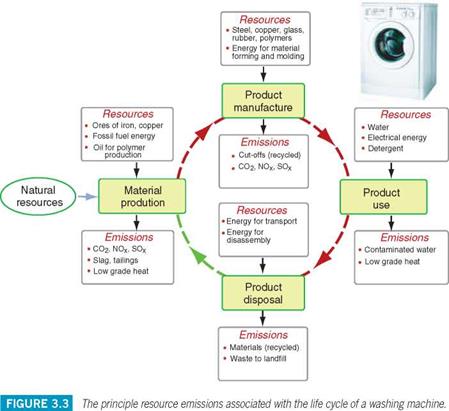

Figure 3.3 is a schematic of the start of an inventory analysis—the identification of the main resources and emissions—here for a washing

|

|

machine. Most of the parts are made of steel, copper, plastics, and rubber. Both materials production and product manufacture require carbon-based energy with associated emissions of CO2, NOx, SOx, and low-grade heat. The use phase consumes water as well as energy, with contaminated water as an emission. Disposal creates burdens typical of any large appliance.

Impact assessment. The inventory, once assembled, lists resource consumption and emissions, but they are not equally malignant; some have a greater impact than others. Impact categories include resource depletion, global warming potential, ozone depletion, acidification, eutrophication,1 human toxicity, and more. Each impact is calculated by multiplying the quantity of each inventory item by an impact assessment factor—a measure of how profoundly a given inventory type contributes to each impact [3]

|

category. Table 3.1 lists some examples of that for assessing global warming potential. The overall impact contribution of a product to each category is found by multiplying the quantity emitted by the appropriate impact assessment factor and summing the contributions of all the components of the product for all four phases of life.

Interpretation. The final questions: what do these inventory and impact values mean? What should be done to reduce their damaging qualities? The ISO standard requires answers to these questions but gives little guidance about how to reach them. All this makes a full LCA a time-consuming matter requiring experts. Expert time is expensive. A full LCA is not something to embark on lightly.

The output and its precision. Figure 3.4 shows part of the output of a partial LCA—here, one for the production of aluminum cans (it stops at the

Resource

Resource

consumption

Emissions

inventory

Impact

assessment

FIGURE 3.4

exit gate of the manufacturing plant, so this is a cradle-to-gate, not a cra- dle-to-grave study). The functional unit is "per 1000 cans." There are three blocks of data: one an inventory of resources, one of emissions, and one of impacts—here only some of them.

Despite the formalism that attaches to LCA methods, the results are subject to considerable uncertainty. Resource and energy inputs can be monitored in a straightforward and reasonably precise way. The emissions rely more heavily on sophisticated monitoring equipment; few are known to better than ±10%. Assessments of impacts depend on values for the marginal effect of each emission on each impact category; many of these have much greater uncertainties.

And there are two further difficulties, both serious. First, what is a designer supposed to do with these numbers? The designer, seeking to cope with the many interdependent decisions that any design involves, inevitably finds it hard to know how best to use data of this type. How are CO2 and SOx emissions to be balanced against resource depletion, energy consumption, global warming potential, or human toxicity? And second, how is it to be paid for? A full LCA takes days or weeks. Does the result justify this considerable investment? LCA has value as a product assessment tool, but it is not a design tool.

Aggregated measures: eco-indicators. The first of these difficulties has led to efforts to condense the LCA output into a single measure, or eco-indicator. To do this, four steps are necessary, as shown in Figure 3.5. The first is that of classification of the data listed in Figure 3.4 according to the impact each causes (global warming, ozone depletion, acidification, etc.). The second step is that of normalization to remove the units (of which there are several in the LCA report) and reduce them to a common scale (0-100, for instance). The third step is that of weighting to reflect the perceived seriousness of each impact; thus global warming might be seen as more serious than resource depletion, giving it a larger weight. In the final step, the weighted, normalized measures are summed to give the indicator.[4] Ecoindicators have found most use in condensing eco-information for the first phase of life, that of material production. Values for materials, when available, are included in the data sheets in Chapter 12 of this book.

The use of a single-valued indicator is criticized by some. The grounds for criticism are that there is no agreement on normalization or weighting factors, that the method is opaque since the indicator value has no simple physical significance, and that defending design decisions based on a

measurable quantity such as energy consumption or CO2 release to atmosphere carry more conviction than doing so with an indicator.