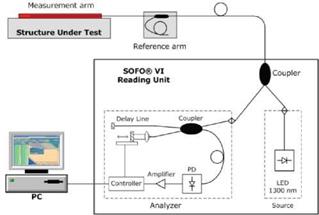

Another type of OFS applicable to composite structures are interferometric sensors (i. e. SOFO® sensors with long measuring arms). Interferometric optical fibre sensors are characterized by the modulation of the light signal phase propagated in the measuring system (Glisic & Inaudi, 2007). The measuring heads of SOFO® sensors, in the form of a single-mode optical fibre, may attain from a few centimetres to a dozen or so meters and are either integrated with the surface of the monitored object (e. g. by means of special tape – SMARTape®) or located inside the monitored structure (e. g. in the case of tested vessels they are buried in the composite). The sensors are designed to measure displacements (deformations). The measurement consists in analyzing the difference in the phases of the optical signals propagating in the two arms (the measuring arm and the reference arm) of the Michelson interferometer (Fig. 2).

|

Fig. 2. Scheme of Smartec SOFO® interferometric measuring system (Glisic & Inaudi, 2007) |

The measuring arm is in direct contact with the examined structure. The reference arm is separated mechanically from the monitored object, but it is still close enough for the temperature of both arms to be the same. Thanks to this the influence of temperature fluctuations on the measurement results is eliminated. The change in the phase of the light wave is a result of the change in the length of the optical fibre constituting the measuring head. Because of the interference of the two beams it is possible – through an analysis of interference fringes – to quantitatively determine the deformation of the sensors and consequently, the deformation of the monitored structure (Glisic & Inaudi, 2007). Since interferometric sensors belong to a group of sensors with long measuring arms (long-gage sensors), the measured deformations are averages for the whole length of the sensor.