A sandwich/spacer fabric is a 3D construction made of two separate fabrics, connected in between by yarns or knitted layers (Ciobanu, 2003). The fabric thickness determined by length of the connecting yarns/layers.

When produced on warp machines, these fabrics are known as spacers. They are obtained on double needle bar machines, with 4 to 6 guide bars – 1 or 2 guide bars produce the independent fabrics by knitting only on one bed and the middle bars create the connection by working on both beds (forming stitches or being in-laid). The fabric thickness depends on the distance between the two beds (spacer distance).

Fig. 22 exemplifies a spacer fabric made of glass fibre. An interesting application for spacer fabrics are the so called textile reinforced concrete that is used in buildings. Liba designed a double needle bar Raschel machine model DG 506-30-2HS that produces spacer fabrics with net structure, as illustrated in Fig. 23. The fabrics present weft and warp in-lays that form the net geometry and give the fabric strength on both directions (source: www. liba. de).

|

|

Fig. 22. Spacer fabric made of glass fibre

|

|

In the case of weft knitted fabrics, they are known as sandwich fabrics. Even if they can be produced also on circular machines (connection with yarns), they are mainly produced on electronic flat knitting machines that offer the required technical conditions and the development possibilities.

The connection can be generated through yarns fed on both beds or by knitted layers. The first solution is limited with regard to shape complexity and fabric thickness. The second connecting principle requires knitting separately on the two beds and at a certain point to stop and knit the connection layer on selected needles, usually 1×1. These needles can work also for the separate fabrics (if the length of the layer is small enough), or can be used exclusively to produce the connection, if the length and/or the shape complexity require (Fig. 24).

|

Fig. 24. Sandwich fabric with connecting knitted layers |

There are two types of connecting layers (Araujo et al., 2000):

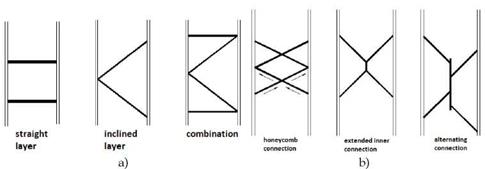

• Single layers (Fig. 25.a) – the layer is produced on one bed (jersey) or on both beds (rib, interlock) and can have a perpendicular or an inclined disposition between the separate fabrics.

• Double layers (Fig. 25.b) – two layers are knitted separately on the beds, connected at a certain point with a rib evolution; if a specified amount of rib courses will be produced also in the exterior fabrics, then the connection will be "X" shaped, with possibilities to extend more the rib dimensions or to alternate the disposition of the two layers.

|

|

The sandwich fabrics presented are characterised by constant thickness and rectangular form in cross section. There are three major ways to diversify these fabrics and to obtain structures with complex shape (Ciobanu, 2003):

• The use of connection layers with different length

• The use of connection layers with variable form (the fashioning/flechage technique)

• The use of exterior fashioned separate fabrics