The information part of the control panel may have different groups of information devices:

1. Overview of information devices:

a. Dynamic

b. Static

2. Specific information devices:

a. Dynamic

b. Static

An overview information device aims to give the operator a general view of the design or status of the process. General information may either be static (for example, a flow chart painted on a wall diagram) or it may be dynamic so that it includes instruments and shows different aspects of the process. A dynamic information device may also contain symbols that change (lights that are on or off depending, for example, on whether a particular valve is open or closed).

The specific information device (usually a cathode ray tube [CRT] screen) is the one from which more detailed information is obtained, such as readings that enable control actions to be made and set values to be implemented. The specific information is often dynamic, but it may also be static, for example, in the form of information in tables and charts.

There should preferably be only two viewing distances: ordinary reading distance (ca. 30 to 35 cm) and long distance (several metres to view the overview panel, for example). When CRT screens are used, a compromise usually has to be made as the screen cannot be placed too close. There may in this case be three normal viewing distances (for people with spectacles, this means the use of multifocal lenses).

It is important that the viewing distance of the CRT screen is not less than 33 cm; preferably, it should not be less than 50 cm. Too small a distance causes great strain on the eyes and normally requires the use of spectacles even for those with normal vision. The maximal viewing distance depends on the size of the information displayed.

All the important visual information, and all the visual information that is used frequently, should lie within the normal viewing area. The maximum viewing area (angle) is that area within which the operator can see the instruments or controls relatively quickly and reliably by moving only the eyes and without needing to carry out any tiring neck or eye muscle movements.

Figure 6.4 shows an example of the recommended dimensions of the control desk for standing work. From the figure it may be seen that a normal line of sight either directly forwards or a little downwards (maximum 10 degrees) is optimal.

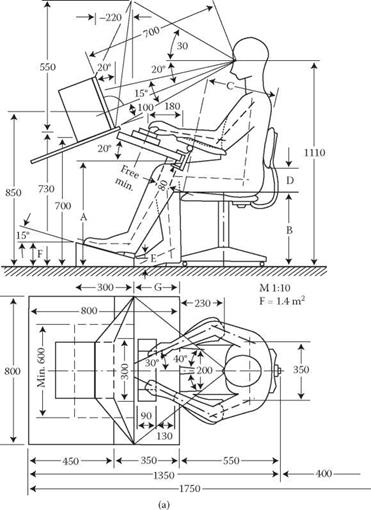

Figure 6.5a shows how a VDU screen should be positioned for ease and comfort of use where the majority of the work is carried out at the VDU screen, a situation that should normally be avoided. Where the VDU work is more sporadic, a flexible positioning of the screen as shown in Figure 6.5b can be recommended.

Most control room applications where VDUs are used require the use of more than one screen. It is usual for at least three to be necessary for the central workplace. These screens are used for different purposes:

1. One for overview information.

2. One for detailed information.

3. One for alarms.

It is also a good idea to have one or more screens at a different, separate workplace for planning work and as reserves.

VDU screens only give information in sequence and only a limited amount of information can be presented at any one time. The overview information as presented on a VDU cannot contain particularly large amounts of detail. Large-scale processes therefore require other types of large-scale dynamic overview panels that can present the whole process in parallel.

|

Work surfaces and controls must be positioned within easy and comfortable reach. This means having an area limited in height, width, and depth, within which the most important controls and work surfaces must be placed. Most types of control room work need plenty of space for carrying out the various tasks, apart from the control tasks as such. One needs, for example, writing surfaces, surfaces on which to place books and manuals, and surfaces for coffee and beverages. We look first at the heights of work surfaces and then at the surface area requirements.

The height of the work surface is of the greatest importance, whether the operator works standing or sitting. An incorrect work surface height results in the operator assuming a bad body posture, which in the short term is tiring and in the long term can cause permanent injury. With this in mind, we shall discuss first the positioning of the work surface itself. It should, of course, be pointed out that one should not view the work surface as an isolated unit, but the work surface, chair, and other equipment should be seen as a whole. Recommendations are given for both sitting

|

FIGURE 6.5(a) Design of a CRT workstation. |

and standing work. Sitting or standing workplaces are recommended for different types of jobs.

Sitting work positions are to be preferred to standing ones in the following cases:

1. In order to reduce fatigue. It is easier for an operator to work using his arms, and do heavier work with his legs, for a longer time when he is sitting rather than standing.

2. So that the operator can use both feet simultaneously and can develop greater force with his legs, use pedals faster, and operate several controls with one or both feet.

/

|

/

3. So that the operator can be protected from vibration while his arms and legs are free to use the controls.

4. When the operator’s workplace is subject to movement. Some additional form of support for the body should be provided.

Standing work is to be preferred to sitting in the following cases (standing here means that the operator has the ability to move about):

1. Where greater mobility is required; by taking a step in a particular direction, the operator can reach considerably more controls.

2. Where the operator needs to carry out larger movements.

3. Where movements that require large force over large distances are carried out.

It is preferable for the work to be done both standing and sitting in turn, especially if the operator can choose when and if he or she wants to stand or sit. The workplace is then designed for standing work, and a high chair is provided. All work surfaces should be adjustable for height, so that they can be set at the height, which best suits each individual. If it is not possible to adjust the surface to the

height required by each person, it is best to set up for the taller person rather than the shorter. A shorter person can then raise the chair, and at the same time use a footstool. A tall person, on the other hand, cannot become accustomed or adjust to working at too low a work height. The recommended heights of working surfaces for standing work are shown in Table 6.1. The recommended heights for sitting work are shown in Figure 6.6 and Table 6.2.

In the literature, several different heights are recommended for working surfaces. This is because sometimes the heights for men and women are differentiated. Alternatively, insufficient degree of adjustability may have been allowed for in the height of the surface or that a footstool has not been allowed for. In the ‘Total’ column in Table 6.2, measurements within which the working surface should be adjustable are indicated.

For sitting work, the work surface should be a few centimetres lower than the elbow height.

|

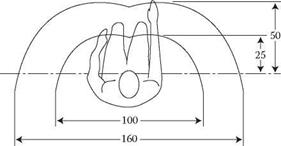

Figure 6.7 shows the areas of a horizontal working surface which can be reached with and without stretching. A workstation in a control room needs a free table surface for drawings, manuals, and handbooks. It must be possible to move the keyboard to increase the available area beside the CRT.

|

TABLE 6.1 Recommended Working Heights for Standing Work Work surface height for standing Work (cm)

Source: Grandjean (1988). |

FIGuRE 6.6 Workplace for reading and writing.

Recommended Working Heights

|

TABLE 6.2 Work surface height for sitting Work (cm)

Source: Grandjean (1988). |

|

FIGuRE 6.7 Vital measurements for all horizontal working surfaces. |