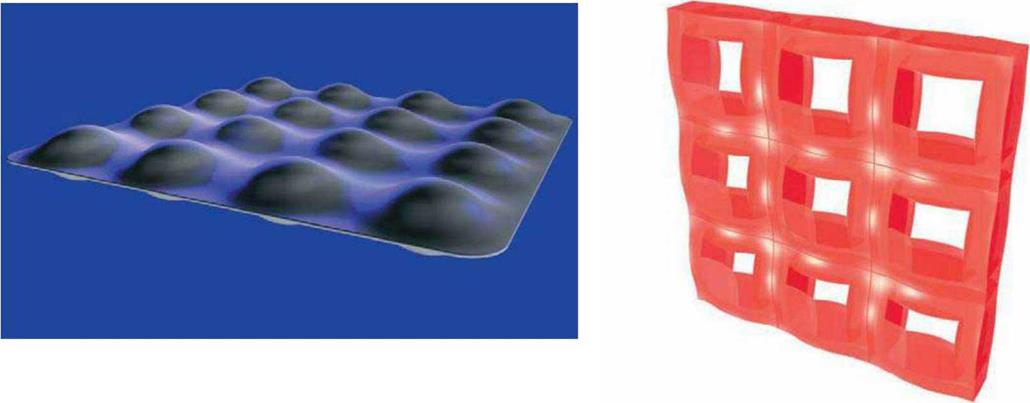

“I decided to give the face of the book unit fluidity, a sense of three dimensions, using the same three dimensional form that I created with the Fruitscape design for Alessi,” he says. “I shifted the Fruitscape form from horizontal to vertical, and projected a square grid onto this curved landscape, creating the book unit modules,” he continues. “It’s funny that this product came from another product. This was the starting point, and it’s something that is very special. I never succeeded to do such kind of transposition before, but I think it fits very well to this product.”

“I decided to give the face of the book unit fluidity, a sense of three dimensions, using the same three dimensional form that I created with the Fruitscape design for Alessi,” he says. “I shifted the Fruitscape form from horizontal to vertical, and projected a square grid onto this curved landscape, creating the book unit modules,” he continues. “It’s funny that this product came from another product. This was the starting point, and it’s something that is very special. I never succeeded to do such kind of transposition before, but I think it fits very well to this product.”

The fruitscape is a “bowl,” which is actually a flat piece of polished stainless steel with mounds dispersed over its surface for nesting individual pieces of fruit. “Each module is a small mountain like a wave,” says Giovannoni. “For the Boogie Woogie, we used the same surface, and I cut off the top of the each mountain. It’s like a projection of a grid where I create holes cutting off the higher level of the surface. Each module of the bookcase corresponds to a module of the fruit bowl.” Fie continues, “I think this kind of transposition is very interesting in this project because if you saw the two together, you would not recognize that they came from the same place.”

The Boogie Woogie unit was developed as a response to a very simple brief from furniture manufacturer Magis: “The bookcase has to be made out of one module that can increase in dimension horizontally and vertically,” according to Giovannoni. “The risk was to create a product that would be very boring. It’s not so easy because I like to create complexity from a very basic briefing. Using this surface, the result creates a product that is not flat, but has a full-dimensional way of creating interesting movement.”

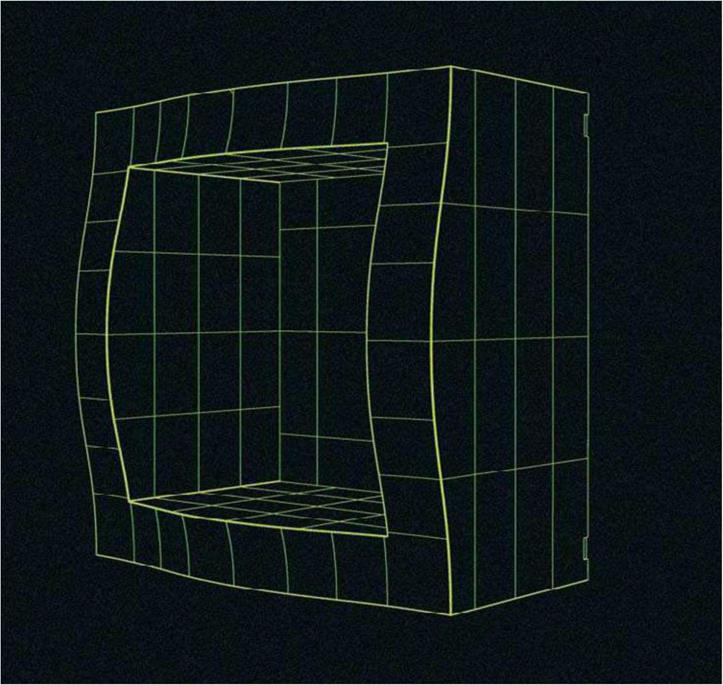

Each module is about 23" (0.6 m) square and made from injection molded ABS plastic in white, black, or red. The sides, bottom, and back of each piece are flat, while the front surface has a marked wave, picked up from the undulations on the Fruitscape. Modules are connected together vertically and horizontally to make a shelving unit of any size. In addition, they can be connected back-to-back to create a freestanding shelving unit or room divider where both the front and back undulate. The backs of individual modules can be left off, so the cubes are open. “The main piece includes the module with the front surface and eight sides —four outside and four inside the hole,” explains Giovannoni. “This is one module, molded in one piece. The other module is the back panel. We have connectors that are made with

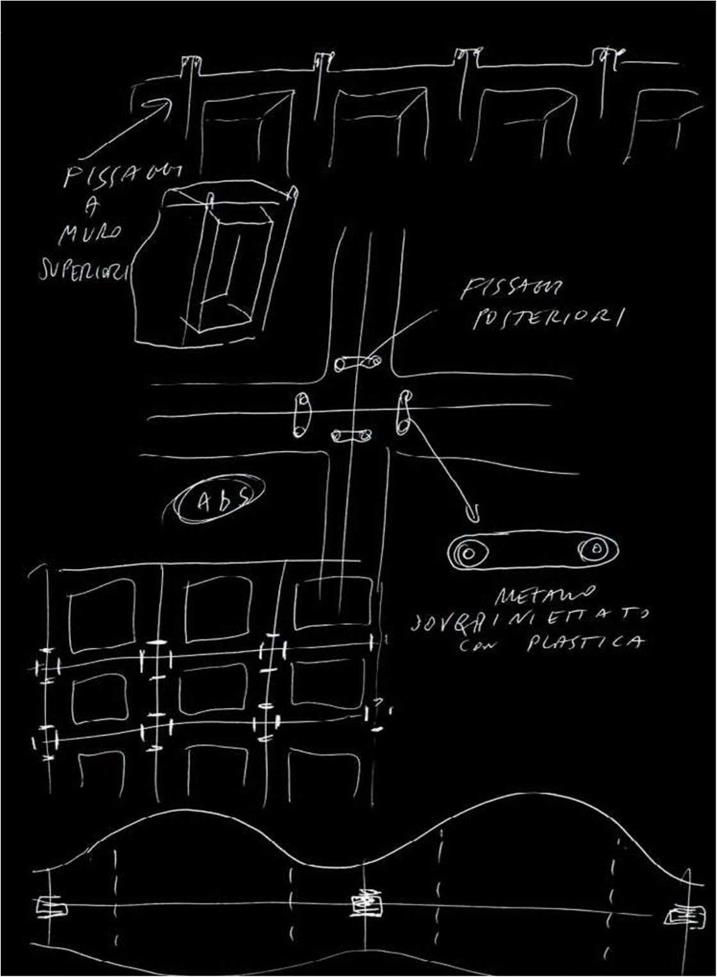

While Giovannoni does almost all his design phases directly on the computer, this early hand sketch shows his concept for metal fasteners embedded in each plastic cube that would allow the units to connect to one another, while maintaining a smooth presentation. Credit: Giovannoni Design

^v^The undulating face of the Boogie Woogie was inspired by a metal fruit holder Giovannoni designed, the Fruitscape (below). By taking the horizontal piece, making it vertical, and skimming the top off the mounds, the Boogie Woogie was born.

^v^The undulating face of the Boogie Woogie was inspired by a metal fruit holder Giovannoni designed, the Fruitscape (below). By taking the horizontal piece, making it vertical, and skimming the top off the mounds, the Boogie Woogie was born.

Credit: Giovannoni Design

© Giovannoni felt that cubes were the best option for the modularity requested in the design brief, but was concerned they’d be too boring, so he gave the front face of each module a pronounced wave.

© Giovannoni felt that cubes were the best option for the modularity requested in the design brief, but was concerned they’d be too boring, so he gave the front face of each module a pronounced wave.

Credit: Giovannoni Design

® Boogie Woogie units are made from individual cubes stacked and connected horizontally and vertically. Back panels can be added to close the units, or they can be left open. In addition, modules can be connected back-to-back to create a doublesided, freestanding room divider that has a wave pattern on both sides.

|

|

Credit: Carlo Lavatori

|

178 DESIGN SECRETS: FURNITURE |

|