“There always has been a kind of joy for me in assembling something and understanding how it works,” says Stephen Burks,

explaining the Not So Soft Table. “The best, most successfully designed objects are those that are immediate, that communicate, in a way, their function, that say what they do.

explaining the Not So Soft Table. “The best, most successfully designed objects are those that are immediate, that communicate, in a way, their function, that say what they do.

I like how this table explains itself, and how it also explains the design process in a way. You get to choose how much of it you put together,” Burks points out, “even if there is only one way to put it together.”

The Not So Soft Table was an unexpected outgrowth of Burks’ work with Mogu, a Japanese manufacturer of pillows filled with polystyrene pellets. During his year or so as international art director for the now defunct company, “I realized they were making things in injection-molded polypropylene. It has a higher oil content that holds pellets together and stiffens them, hardens them. I wanted to take a minimum wall thickness of material, and try to conceive a piece of furniture that could be made from a single molded part. This way,” Burke continues, “the tool would be smaller, you’d use less material, and you could make the piece as big or small as you want. We had two months before the Milan Furniture Fair, so in two months we designed the Not So Soft Collection. The table reminded me, in a way, of Mogu’s other products, but it was less soft.” Flence, the name.

The very odd shape of the component parts for table and chair were a direct product of considering the practical issues associated with the manufacturing. “We knew it had to be a solid because of the strength issues related to the material,” says Burks. “We couldn’t do anything with legs because that would have been too fragile. We wanted to work from a solid base, and from that, come up and form a seat and a back. There’s no formalism in it per se,” he notes. “The rounded corners were softened basically because it seemed to fit the aesthetic.”

Burks feels that although this process was entirely new to him, and he had never designed a chair before, the Not So Soft collection is clearly another expression of his design process and concerns. “I try to do what’s right for my client,” he says, “and I saw this as a chance for them to do something totally proprietary. The idea of taking a smaller part and making a bigger product is consistent in my work because I am interested in conveying the kit- of-parts nature of design. All products have a kind of assembly,” Burks explains. “I think design can be communicative in that way and can engage the user in understanding and using the product. It’s a way of making design accessible. The process is actually communicated through the form and the function of the thing. Not just the design process, but the manufacturing and assembly process as well. Some people interpret this as a playful nature in my work, others call it a kind of ready-made utility, but for me it’s a matter of communicating the process.”

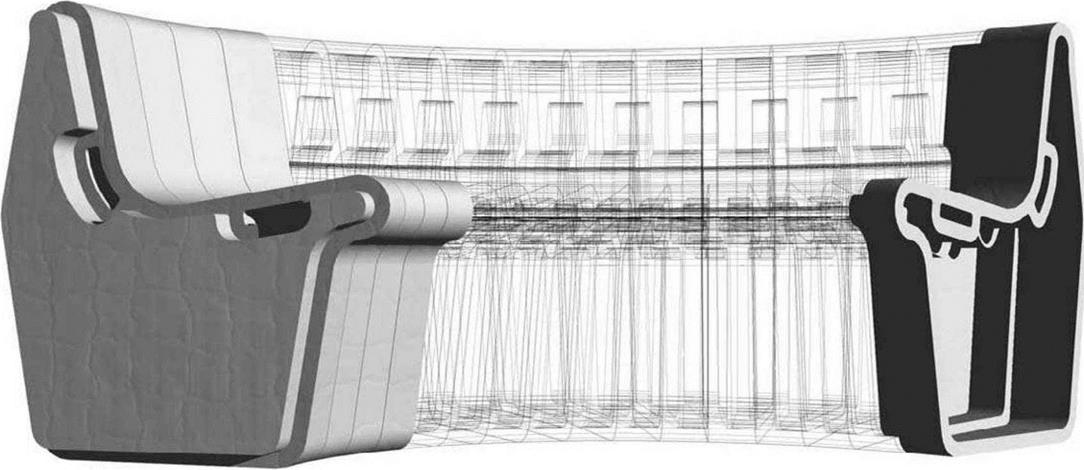

Burks and Mogu found a factory that was using injected molded polypropylene to make automobile bumpers. They had never manufactured furniture, but happily jumped into the project and made a mold for the parts to both the chair and table. “They cranked out a bunch of pieces, and we used them to make a circular seating arrangement and a circular table,” recalls Burks. “They friction-fit together. They are designed for very little tolerance between the pieces and the material compresses a bit, so they push together with a very satisfying squeak. Four parts made a chair, twelve parts a love seat, forty-eight parts made a circular chair. The parts are actually curved, smaller at front and bigger at the bottom,” Burks notes. “With the table, we did the same thing with a different part. Twenty-four parts make the table. It was a great thing—lightweight, outdoor, indoor, it floats. We didn’t do color because it’s much more expensive, so we did it all in black and white.”

Burks and Mogu found a factory that was using injected molded polypropylene to make automobile bumpers. They had never manufactured furniture, but happily jumped into the project and made a mold for the parts to both the chair and table. “They cranked out a bunch of pieces, and we used them to make a circular seating arrangement and a circular table,” recalls Burks. “They friction-fit together. They are designed for very little tolerance between the pieces and the material compresses a bit, so they push together with a very satisfying squeak. Four parts made a chair, twelve parts a love seat, forty-eight parts made a circular chair. The parts are actually curved, smaller at front and bigger at the bottom,” Burks notes. “With the table, we did the same thing with a different part. Twenty-four parts make the table. It was a great thing—lightweight, outdoor, indoor, it floats. We didn’t do color because it’s much more expensive, so we did it all in black and white.”

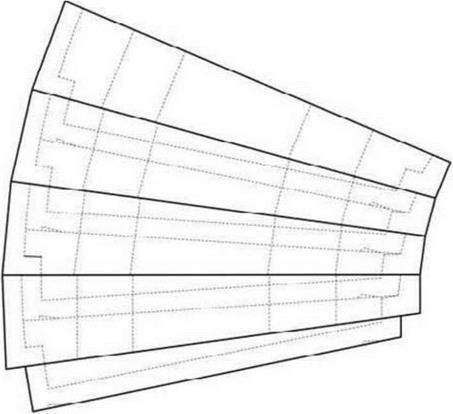

© Top left: The basic outline of the Not So Soft Table and Chair take shape in these study models; however, manufacturing considerations and the commitment to use only two pieces eventually dictated that the table be made without legs. Credit: Readymade Projects

0 Top right: Injection molding tooling of the two parts required to make the Not So Soft products. The small nubs are where the pieces will be snapped together. Credit: Readymade Projects

@ The first prototype of the Not So Soft Chair. Only four pieces are required to create a stable footprint, and the final product is surprisingly lightweight. Credit: Readymade Projects

|

|

© A technical drawing of the Not So Soft Chair component reveals the thin layer of material that is used, as well as the pins that allow multiple pieces to be snap-fit together. Credit: Readymade Projects

(a) This assembly illustration demonstrates how four Not So Soft pieces create a comfortable chair, while adding a dozen more parts adds up to a circular bench.

Credit: Readymade Projects

@ The Not So Soft Chair parts fit together like an adultsized toy, transforming itself from odd-shaped pieces of plastic into a multifunctional chair.

Credit: Miro Zagnoli

Burks recalls the thrill of seeing the parts come out of the mold. “There was a real sense of excitement,” he says. “They looked at this thing and held it up —it weighs nothing—and the engineer went to piece it together, and he was so excited, he sat down and put his thumbs up.” He points out that it was especially gratifying to take an industrial process that is focused on one particular industry and transfer its processes to a completely different industry. Plus there’s just something fun about the Not So Soft. “It’s really exciting to see people put it together,” says Burks. “It’s a kind of giant toy.”

While the Not So Soft line was quite a hit at the Milan Furniture Fair, it unfortunately never went to full production because Mogu went out of business. Strangely, the company was a victim of their own success. They were not able to fulfill the massive quantity of orders they generated for their pillows, and also did not protect the propriety of their product, which was copied and knocked off endlessly by other companies. Burks is both wistful and philosophical about the unfinished piece of business the Not So Soft represents. “I think half of our work as designers is entrepreneurial,” he says. “People don’t want to admit that this business is speculative. You go out there with your suitcase and your vacuum cleaners, and say this is what I’ve got. Young designers all want to know how did you do this or that, and they don’t understand that you just go and talk to people and you try to communicate that you have something to offer.” Burks remains committed to the Not So Soft. “The design was very successful and it communicated what I wanted it to,” he says. “It’s potential was huge, but it’s still a dream unfulfilled until I can find a way to get it out there.”