In the case of the paper softwall, the initial inspiration was picked up at a dollar store. Working with expandable paper party decorations, Forsythe and her partner, Todd MacAllen, began looking into the expandable properties of tissue paper honeycomb, and the kinds of interesting 3D structures they could create. At the same time, “. . . we were also working on housing in Japan, at ways of making private space more flexible,” says Stephanie. “In urban living, space is at a premium. We wanted to take these realities and find solutions that contribute to the quality of life and the free flow of air and light.” With these concerns in mind, they began to imagine what would happen if they took one of those paper lanterns and made it much, much bigger.

In the case of the paper softwall, the initial inspiration was picked up at a dollar store. Working with expandable paper party decorations, Forsythe and her partner, Todd MacAllen, began looking into the expandable properties of tissue paper honeycomb, and the kinds of interesting 3D structures they could create. At the same time, “. . . we were also working on housing in Japan, at ways of making private space more flexible,” says Stephanie. “In urban living, space is at a premium. We wanted to take these realities and find solutions that contribute to the quality of life and the free flow of air and light.” With these concerns in mind, they began to imagine what would happen if they took one of those paper lanterns and made it much, much bigger.

The next step was to find a willing fabrication partner. They found a company in Pennsylvania that had been making paper party decorations for more than 100 years, and asked how big they thought they could take honeycombed tissue paper. “They were open-minded. It didn’t faze them to go from paper wedding bells to walls,” Forsythe reports. While the company only had to make small adjustments to existing machinery to accommodate molo’s vision, they did find they needed to set aside a special room where they could warm the air to the proper temperature to cure the glue on this larger scale. Little by little, they worked up prototypes that increased in size from a column to a wall. Along the way, they discovered the material behaves differently as it grows. At first, with only fifty layers of paper, they found the honeycomb would spring closed. But by adding more layers, it would hold itself open, creating an expandable, flexible wall that absorbs sounds, captures and then diffuses light, and offers a uniquely soothing ambience through its delicate yet sturdy structure.

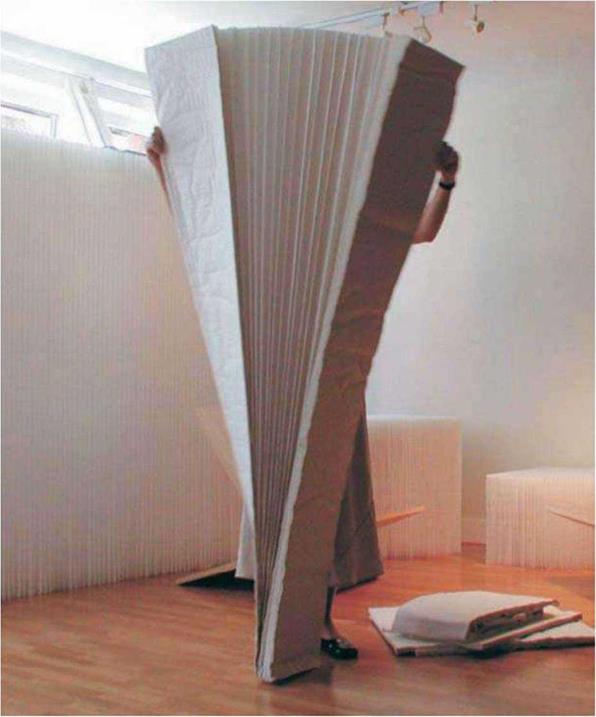

To add durability and handling ease, molo attached wool/felt end covers. To extend the wall, one holds onto the felt and pulls. “It sounds like rain, when you open it,” Forsythe says. There are also Velcro® strips attached to the felt that allow one wall to be attached to another, for extra length or modularity. The felt can also be folded lengthwise so it sticks to itself, creating a column that gives additional support to each end. Finally, when the wall is collapsed on itself, it can simply be hung up in a closet, where the felt ends make it resemble nothing so much as a rolled blanket. “It’s a bit like wrapping a book in a book cover,” Forsythe points out. “We’re giving the surfaces that get handled a lot a soft, yet sturdy, material. And felt has an affinity for the paper,” she points out. “Felting and papermaking have a natural relationship.”

|

192 DESIGN SECRETS: FURNITURE |

|

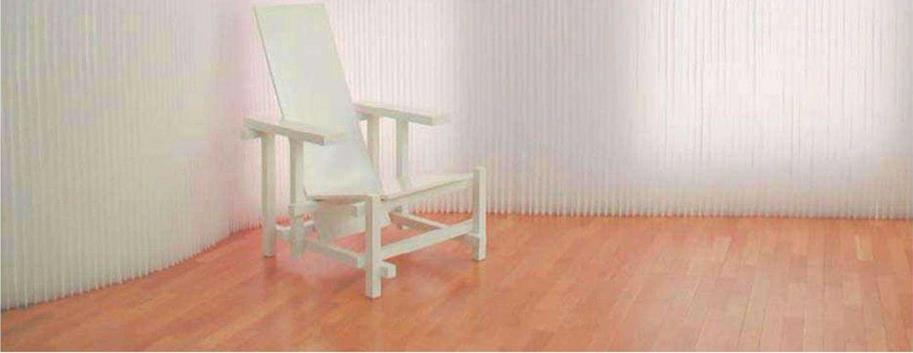

The tissue paper honeycomb is stronger than it appears, with each sheet gaining strength from every other. Yet, it retains its delicacy and allows light to penetrate. Credit: molo design

By pulling the two ends of the paper soft – wall apart, a self-supporting wall is released, accompanied by a sound not unlike a gentle rainfall, according to the designer. Credit: molo design

By pulling the two ends of the paper soft – wall apart, a self-supporting wall is released, accompanied by a sound not unlike a gentle rainfall, according to the designer. Credit: molo design

In part, the beauty of the paper softwall comes from its stunning simplicity. Which is, in turn, the direct result of molo’s design sensibility. Trained as an architect, Forsythe says, “The headache always comes down to where materials are joined, and no one wants to take responsibility for the joint. There are so many possibilities when you simplify things. There’s this idea of focus, of paying attention to one material and seeing what it can do.” Plus, there are practical concerns that make it easier to modify what already exists. “Our general philosophy is to look for existing tools and infrastructure. After all, we can’t afford to make our own machines,” she says, “so we look for materials that are out there and for new ways they can be used.”

The base material of the softwall is 400 layers of off-the-shelf tissue paper treated with flame retardant. The resulting product is surprisingly durable; Forsythe reports that the family dog, as well as a couple of young, rambunctious nephews have not been able to damage the paper softwall they use in the studio. “If you bump into it or the dog runs into it, the wall has so much flex, it just bounces away,” she says. “And the honeycomb structure means each individual sheet borrows from the others for strength. But we look at it like we’re living with a Japanese Shoji screen, which gets patched over time, only adding to its character. The same can happen with the softwall.” Still, it is paper and water will destroy it, so molo design has introduced a softwall made from a non-woven polymer textile. In addition, they are looking at working with artists to create unique, limited editions of paper softwalls.

Molo design is also exploring other building and product possibilities for paper honeycomb. They are making smaller versions with an interior tunnel that could hold a lightbulb, creating a cool-to-the-touch, space efficient, ambient lamp. They’re also looking at embedding LEDs into the honeycomb to create a collapsible lamp. But the most exciting possibilities involve increasing the product scale even more. Working with Common Ground, a New York City nonprofit looking to use innovative design solutions to address the homeless problem, molo design is creating full rooms of collapsible, single occupancy housing made from honeycomb textile. They are currently working on a test program that puts these rooms into a raw space in New York’s Bowery neighborhood. While there are many concerns with everything from fire codes to wear and tear from constantly shifting tenants, Forsythe feels these are surmountable challenges that can allow the softwall to become an important addition to the catalog of building-system possibilities.

Molo design has made the paper softwall commercially available at two standard heights of 6′ (1.8 m) tall and 4′ (1.2 m) tall. Both are i’ (30 cm) thick and expand from 17" (4 cm) when closed, up to 2o’ (6.1 m) long. Molo created a buzz when they used early prototypes of the paper softwall for their own booth at the ICFF (International Contemporary Furniture Fair) in May 2004; the 2005 show marked their official product launch. But even before its commercial introduction, the paper softwall was awarded a jury pick from Architectural Record magazine as one of the best products of 2004, and New York’s Museum of Modern Art recently added a paper soft – wall to their permanent collection.

In the meantime, Forsythe and MacAllen have been carting soft – walls to museum shops and potential retail outlets. “We can fit two paper softwalls into our suitcases,” she says. “It’s really funny when we bring them out and put them up in a store or on the sidewalk. People giggle as it opens, and then keeps opening and opening to 2o’ (6.1 m) or more. They can’t believe this much wall can come from just 17" (4 cm) of thickness.”