With the advent of the computer and computer-aided design (CAD) devices, computer programs fueled the development of computer-aided manufacturing (CAM) and the use of CNC devices. These devices were initially expensive machines used for mass-produced items such as cars and planes, but recently they have begun to emerge in smaller and mid-sized craft shops throughout the world. CAD/CAM technologies have become firmly established and will likely become the means to design and fabricate a greater percentage of furniture in the future.

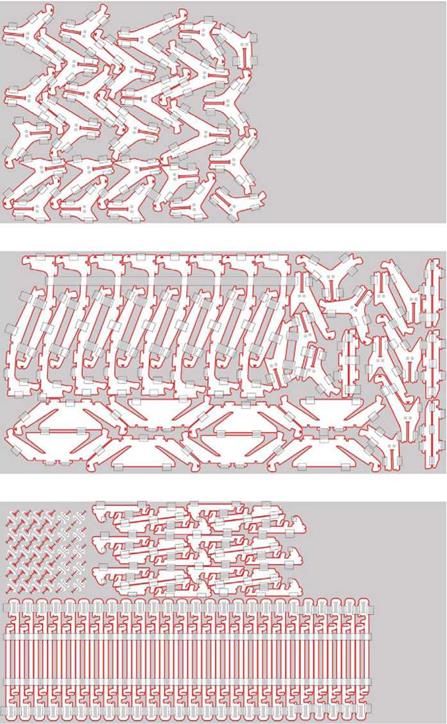

During the 1980s, furniture companies began to invest in technology to achieve complicated cutting operations in a rapid, precise, and repetitive manner. Today, many furniture designers and companies use CAD software to produce digital geometric models and CAM software to specify how the digital design model will be fabricated. CNC devices translate the digital instructions into machine cutting operations to produce the furniture (Figure 8.56).

|

Figure 8.56 Nested layout of furniture components by Jeff Welch. Digital tool path file with lower perimeter cuts with tabs, prepared by Brian Ringley, Rapid Prototype Lab, College of DAAP, University of Cincinnati. Digital file courtesy of Brian Ringley, 2012. |

As smaller and mid-sized shops began to acquire digital technology, traditional craft methods began to incorporate CNC devices in the design and production of new works. Blue Dot. com, Ply Architects, Hariri and Hariri, John Nastasi, Steven Kieren, and James Timberlake are some of the many design and architecture firms that have begun to achieve high quality of work provided by digital software and CNC devices.