Fabrics and leather are materials commonly used where furniture comes into direct contact with the human body. Fabric is a generic name given to natural and synthetic textiles.

|

|

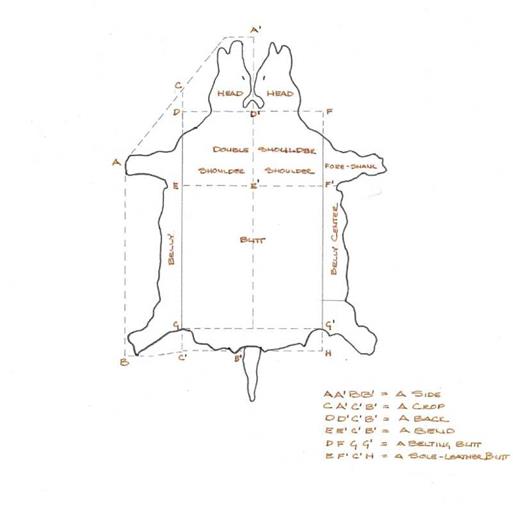

Leather is the generic name given to animal hides prepared by a currier (Figure 7.31). Large animals are said to have "hides" (cow hide, buffalo hide), while smaller animals have "skins" (goatskin, sheepskin). Conventionally, leather upholstery calls for a thickness of 1.0 to 1.2 mm, or 2Уг to 2% oz. per square foot. Originally, hides were preserved using smoke of tannin-containing woods in tanneries. Tanneries were named after tannins, a neutral phenolic compound found in plants such as grapes, oak, and teas. Hides were soaked in a

series of tannic acid baths for several days and dried in the sun over a bed of shredded wood.

series of tannic acid baths for several days and dried in the sun over a bed of shredded wood.

Historically, fabrics and leather have been used on seat pans, upholstery covers, cushions, wall hangings, the arms of chairs, writing desks, and writing surfaces; to reinforce joints; and for selective uses as hinges. In the Middle Ages, some tables were covered with tapestries. Today’s sofas and chairs are typically upholstered in wool, cotton, leather, synthetic leather, nylon, rayon, spandex, and micro fiber. The upholstered cushion in Figure 7.32 is covered with velour and functions as a hybrid between a beanbag and a portable pillow.

Some low-cost leather furniture uses genuine leather for cushions and backrests, while synthetic leather is used in high – friction areas such as armrests and at the base where shoe scuffs do the most damage. This increases the life of the furniture and minimizes the need for maintenance and repair.

Leather contracts as it becomes dry and expands with increases in humidity, and most notably, it breathes. Care should be taken to prevent excessive sunlight from fading and drying leather.

Genuine leather is available in various processed forms and has what is called a soft hand. Naturally dyed leather tends to show imperfections, grain, wrinkles, and veins more than synthetic leather. Naturally dyed leather ages well because there is no topcoat to crack with age. While this can make it more susceptible to natural oil stains, scrapes, and scuffs, these contribute to the deep, rich patina that leather gains with age. Lighter colors tend to show natural wear faster than deeper colors.

Leather is first dyed, and then a protective layer is absorbed into the surface to prevent staining, scuffing, and scarring, resulting in a semisoft hand. This provides excellent durability and is ideal for environments with children and pets. A manufacturer’s recommended treatment can be used to prolong the life of leather and prevent unsightly cracking caused by long exposure to hard use and UV rays.

In 1938, the Argentinean architects Jorge Ferrari-Hardoy (1914-1977), Juan Kurchan, and Antonia Bonet designed the Sling/Butterfly chair. In its original conception, it was made using canvass stretched over a wooden frame, later composed of two iron frames covered in a canvass or leather sling. The form of the chair is based on a nineteenth-century folding wooden British officer’s chair. The Sling/Butterfly chair shown in Figure 7.33 has full-grain leather sling upholstery with strengthening repair to the underside. Initially manufactured by Artek and Knoll, the chair is 34.5 inches (87.6 cm) high; 32 inches (82 cm) deep; and 30 inches (76.2 cm) wide.

The Cab chair is a full-grain leather chair designed in 1977 by Mario Bellini for Cassina. The first Cab was designed without arms, utilizing a steel frame and a plastic internal diaphragm incorporated directly under the seat pan to offer support and reinforce the leather seat. The full-grain leather slips over the metal frame and zips up along the inner seam of each leg. All seams are sewn together using polyurethane threading, and the end grain of the exposed leather seams is dyed black. In 1979, a second Cab chair with arms was designed and produced (Figure 7.34).

|

|

Synthetic leather is durable. It won’t stain easily, and does not feel as soft as natural leather. It is generally colder to the touch than genuine leather and will heat up in direct sunlight. It is generally nonporous; therefore, it does not breathe well. It is this quality, however, that enables synthetic leather to resist liquid and oil stains. It does not require treatment, but can crack with age if an inexpensive synthetic material is chosen. Enormous strides have been made in creating synthetic leather products that wear and feel like genuine leather.

Gilt leather, often called Spanish leather, was made from calves’ skins faced with tin foil. Gilt leather is embossed or punched with patterns, which are then painted. Tooled leathers are produced in a similar manner. Gilt leather was extensively used for upholstery coverings and wall hangings.