In this chapter, 25 furniture case studies are organized chronologically. Text descriptions, computer-rendered images, hand drawings, and photographs help present the context and background, tectonics, and aesthetics of the studies. The studies present ideas about sitting, working, storing, and partitioning space and present a spectrum of furniture types, fabrication techniques, and social-use examples within the broader spectrum of place and time.

As you read through the studies, reflect upon the chronology and historical context in which each of the selected pieces were designed and fabricated.

Overview of furniture case Studies

Greek klismos chair European cassone, chest, coffer

Greek klismos chair European cassone, chest, coffer

French Rococo commode, by Jean Baptiste/J. B. Hedouin, stamped JME Chippendale chair, designed and fabricated by Thomas Chippendale Cafe chair, Model No. 14, designed by Michael Thonet, manufactured by GebrQder Thonet

Roadblauwe Stoel (Red-Blue chair), designed and fabricated by Gerrit T. Rietveld Blocs Screen, designed by Eileen Gray

Wassily club chair, designed by Marcel Breuer, fabricated by Standard Mobel/ Lengyel/Knoll International

Siege a Dossier Basculant (B301), designed by Charlotte Perriand, Pierre Jeanneret, and Le Corbusier, manufactured by GebrQder Thonet, H. Weber, and Cassina Stools 60/65, designed by Alvar Aalto, manufactured by Artek Eames Storage Unit (ESU), designed by Charles and Ray Eames, produced by Herman Miller

Antony chair, designed and produced by Jean Prouve

Wire side chair, designed by Harry Bertoia, produced by Knoll International

Action Office, designed by Robert Propst, produced by Herman Miller

Ghost chair, designed by Cini Boeri and Tomu Katayanagi, produced by Fiam Italia

Cross Check armchair, designed by Frank Gehry, produced by Knoll International

Trinidad chair, designed by Nanna Ditzel, produced by Fredericia Stolefabrik

Living Units, designed and fabricated by Andrea Zittel

Aeron chair, designed by Don Chadwick and Bill Stumpf, for Herman Miller

The Block, designed and fabricated by Erik Skoven

Pathways, manufactured by Steelcase

Jimmy’s Buffet, designed and fabricated by Jim Postell, Janet Flory, Steve

Wethington, and Matthew Cornell

Knit chair, designed by Emiliano Godoy, GODOYLAB

Araneae coffee table, designed by Greg Lewis, Pleat Design

Vitrine Modular System, designed by Stephen Slaughter

Neither a throne nor a stool, the klismos chair was unique in both form and social use and has been cited as the most characteristically Greek of all chairs.1 The klismos chair is both graceful and functional, combining comfort, simplicity, and elegance in one typological form whose proportions evolved over several hundred years. It is assumed to have been a relatively light chair, with a curved back and outwardly curved legs. It was easily portable. Gisela Richter referred to the klismos as "the chair with [a] back"2 because she considered it a throne for everyday use. Based on surviving representations on vases, paintings, and sculptural relief (Figure 4.1), the klismos chair is often associated with domestic life, depicting women who appear to be dining or seated comfortably.

From carefully executed depictions on vase paintings and other sources, it is possible to obtain a fairly clear idea about the design and fabrication of the klismos chair. The back and legs were generally plain, but their angle, proportion, and profile varied. The back ended in a curved horizontal board at about

From carefully executed depictions on vase paintings and other sources, it is possible to obtain a fairly clear idea about the design and fabrication of the klismos chair. The back and legs were generally plain, but their angle, proportion, and profile varied. The back ended in a curved horizontal board at about

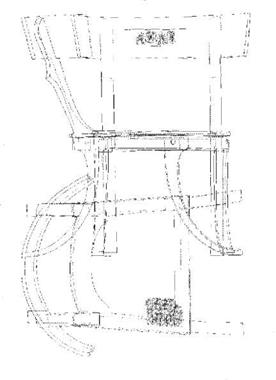

the height of the shoulders and was supported by two or three uprights. The stiles and rear legs were made, as a rule, in one piece. This helped to achieve the fine, continuous curve of its profile. The frame pieces of the seat were mortised into the legs with tenons or dowels. The tenons passed through the upright bars and sometimes protruded through the sides of the legs. Wood joints were held together with tenons (or dowels), hide glue, and nails. The seat frame was never higher than the top of the legs. Generally, the front legs terminated in pointed projections extending slightly above the seat frame. Drapery, fabric, animal hides, and pillows were placed on the seats (Figure 4.2).

The dimensions of the computer-rendered images (Figures 4.3 and 4.4) are estimated and based on interpolated dimensions of the klismos chair: 36 inches (85 cm) high, 30/ inches (77 cm) deep, and 20 inches (51 cm) wide.3 Significantly, no two klismos chairs were exactly alike. Each chair was a unique handcrafted creation.

The klismos chair marks a correlation between furniture design and the political ideology of Greek democracy, expressing dignity and providing practical comfort to the individual user. The chair evolved over a period of 300 years into a remarkably well-proportioned design whose formal characteristics and elegant fabrication techniques have inspired many designers throughout history. It served as a precedent for Roman chairs and was resurrected

|

|

|

|

as a source of inspiration for the French Directoire and English Regency styles during the 1800s. The painter and architect Nicolai Abildgaard fabricated a version of the klismos chair in 1800 when neoclassicism emerged as the dominant style throughout Europe. By that time, the United States was politically secure and found individual and expressive freedom in the Federal style, whose source of inspiration came from Greece. For a young, emerging democracy, the Greek ideal was the preferred standard on which to cultivate a new society.

as a source of inspiration for the French Directoire and English Regency styles during the 1800s. The painter and architect Nicolai Abildgaard fabricated a version of the klismos chair in 1800 when neoclassicism emerged as the dominant style throughout Europe. By that time, the United States was politically secure and found individual and expressive freedom in the Federal style, whose source of inspiration came from Greece. For a young, emerging democracy, the Greek ideal was the preferred standard on which to cultivate a new society.

Coffers first appeared in the 1200s as an ornamented chest with a substantial lock added for security purposes. The furniture type and form were quickly adopted by many European countries and adapted as a place to store family treasure. The word coffer is both a verb and a noun. As a verb, it comes from the action of putting money or valuables in a strongbox. As a noun, it refers to a chest, box, supply, or store for keeping valuables or money safe, often belonging to a particular organization.

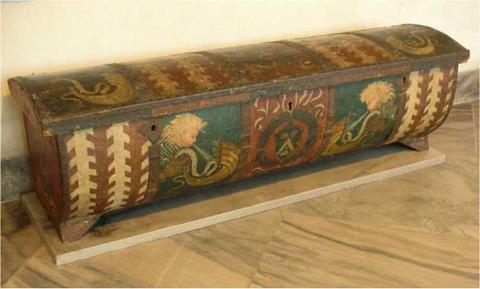

The cassone was a chest. It could be made small for storing jewelry, used for storage while traveling, or made large to serve as a wedding or dowry chest (Figures 4.5 and 4.6).

|

|

|

|

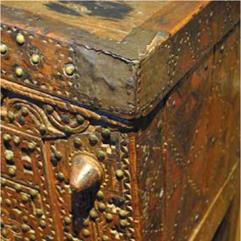

Figure 4.7 Italian cassone, c. 1460. Photography, courtesy of Cincinnati Art Museum. Gift of Mrs. Daniel H. Holmes in memory of Daniel H. Holmes. Accession No. 1933.9. |

|

Figure 4.8 Northern European Hope Chest. Painted wood with metal strapping and three locksets (ca. 1200). Photography by Jim Postell, 2006. |

Traditional marriage chests were carved, gessoed, gilded, or painted to tell a story about the families of the couple being wed (Figure 4.7). They were typically produced in sets of two. One was fabricated for the bride and the other for the groom. They were quintessential^ mobile, traveling with the bride and groom to establish their new home. These dowry chests, which contained the bride’s dowry and the couple’s personal possessions, became principal interior furnishings and were displayed prominently in the home. This tradition was carried into the twentieth century as a hope chest to store household textiles and items, but it became more of a repository for symbolic or decorative memorabilia.

Commodes first appeared at the beginning of the 1700s at the court of Louis XIV (Figure 4.9). The furniture type and form were quickly adopted by other countries and adapted to particular needs. The word commode comes from the French word commodite and the Latin word commodus—both of which mean "convenience."4 The two-drawer commode illustrated in this study was typical, but later versions during the Regency period had three drawers.

The front of the commode was treated as a single element, and the visual distinction between the drawers and the frame was generally ignored. The compound curve that is apparent in cross-section is known as bombe, while the curves apparent in plan view are described as serpentine. The commode has a cambered form with a curved apron and high-curved supports. Decorative cast metal mounts made of bronze protect the feet of the legs. The commode has a continuous %-inch (2-cm)-thick, highly variegated marble slab as the top, which was typical of the commodes produced between 1745 and 1750. The commode stands З8У2 inches (96.5 cm) high (Figure 4.10).

During the French Rococo period, there existed a strictly controlled guild system for fabricating a wide variety of furniture, as shown in Figure 4.9. Ebenistes were makers of veneered furniture, menuisiers were makers of solid-wood furniture, fondeurs were makers of metal mounts, ciseleurs were makers of bronze chasing, vernisseurs were lacquer – ers, marqueteurs were makers of marquetry, and doreurs were gilders. The commodes produced during the French Rococo period engaged a majority of these trade guilds, and the quality of their workmanship was remarkable (Figures 4.11 and 4.12).

Figure 4.9 An eighteenth-century Louis XV oak-paneled room. Photography courtesy of Cincinnati Art Museum. Gift of Mrs. Herbert N. Straus. Accession No. 1958.256.a-h.

Figure 4.9 An eighteenth-century Louis XV oak-paneled room. Photography courtesy of Cincinnati Art Museum. Gift of Mrs. Herbert N. Straus. Accession No. 1958.256.a-h.

|

|

|

|

Figure 4.12 French commode by Jean Baptiste/J. B. Hedouin (1750), corner detail. Photography by Jim Postell, 2006.

Figure 4.12 French commode by Jean Baptiste/J. B. Hedouin (1750), corner detail. Photography by Jim Postell, 2006.

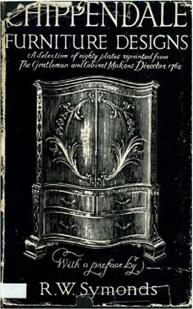

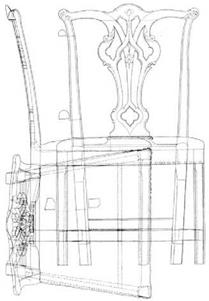

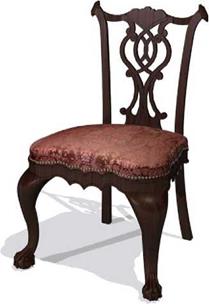

Born in Yorkshire, England, in 1718, Thomas Chippendale was the son of a joiner (a person trained in woodworking and carpentry). The Chippendale chair was a generic design that could be customized in a number of ways to suit different clients. The eighteenth-century armchair could have had any number of carved back splats and various leg profiles incorporated into the design. It was renowned for its exquisitely carved decoration, cabriole legs, and elaborate chair backs (Figure 4.13).

The Chippendale chair is a transitional piece designed at a time when furniture was shifting from being designed and fabricated exclusively for the aristocracy to being marketed and produced for the upper middle class. Chippendale’s booklet The Gentleman and CabinetMaker’s Director (first published in 1754, and later in 1762) illustrated various household furniture designs that could be ordered and reproduced around the world (Figure 4.15). His notes and illustrations in The Director were explicit, citing limitations in the height of the seat backs, allowable variations in design for the front legs of the chairs, and upholstery guidelines for the seat pans (Figure 4.14). The Director was the first published book that was devoted solely to furniture. It was subscribed to by cabinetmakers, upholsterers, clients, and craftsmen and was widely influential. His overall work in furniture, and particularly his Chippendale chair,

The Chippendale chair is a transitional piece designed at a time when furniture was shifting from being designed and fabricated exclusively for the aristocracy to being marketed and produced for the upper middle class. Chippendale’s booklet The Gentleman and CabinetMaker’s Director (first published in 1754, and later in 1762) illustrated various household furniture designs that could be ordered and reproduced around the world (Figure 4.15). His notes and illustrations in The Director were explicit, citing limitations in the height of the seat backs, allowable variations in design for the front legs of the chairs, and upholstery guidelines for the seat pans (Figure 4.14). The Director was the first published book that was devoted solely to furniture. It was subscribed to by cabinetmakers, upholsterers, clients, and craftsmen and was widely influential. His overall work in furniture, and particularly his Chippendale chair,

design on an English chair that was imported to Boston around 1750 and on the design plate from The Gentleman and Cabinetmaker’s Director. Photography by Jim Postell, 2011.

|

|

||

|

|||

became synonymous with the highest quality of late-eighteenth-century furniture design (Figure 4.16).

All intersecting wood members were held together using mortise – and-tenon joinery. The chair’s splats and the marlborough legs are signature components of the chair’s design. Thomas Chippendale was able to inventory a variety of splats and legs, which enabled quick delivery for the made-to-order chairs. French Rococo designs, as well as the interiors and furnishings of the Adam brothers, who had returned from Italy by 1760, added inspiration to the carved pieces.

During the mid-1700s, the trade of upholsterer equaled that of cabinetmaker in importance. There were as many upholsterers as there were cabinetmakers, and many firms advertised doing both. The Chippendale chair depended on the careful integration of both trades. Made from hardwood mahogany discovered in Central and South America, the chair shown in Figures 4.17 and 4.18 is 39 inches high and 28 inches wide (100 cm high and 71 cm wide).

Chippendale had a significant reputation and influence on furniture design around the world. He was a good craftsperson, but also one of the greatest entrepreneurs and businessmen in furniture up to the mideighteenth century. His work was sold around the world, and quickly became a status symbol, satisfying an acquisitive society.

Chippendale had a significant reputation and influence on furniture design around the world. He was a good craftsperson, but also one of the greatest entrepreneurs and businessmen in furniture up to the mideighteenth century. His work was sold around the world, and quickly became a status symbol, satisfying an acquisitive society.

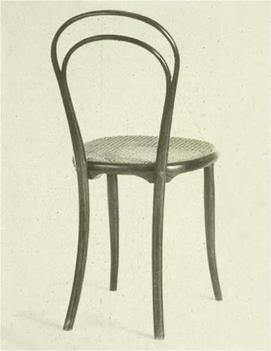

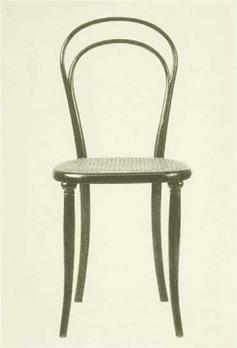

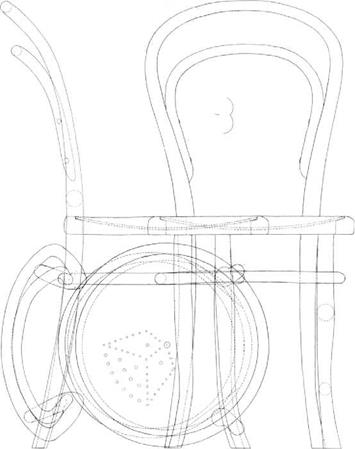

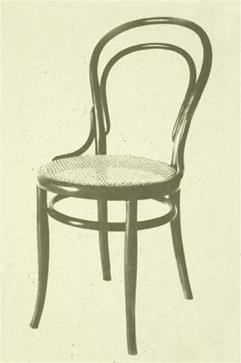

Michael Thonet (1796-1871) created the Austrian furniture company GebrQder Thonet in Vienna in 1853 with his five sons. The bentwood process of 1840, developed by Thonet, revolutionized the production of furniture. Almost immediately, the company experienced enormous success through the mass production of steam-bent and flat-pack beech wood chairs. Le Corbusier selected the side chair Model No. 14 for inclusion in his influential Pavillion de l’Esprit Nouveau at the Paris 1925 Exposition des Arts Decoratif et Industriels Modernes. By 1925, it was the bestselling of all bentwood Thonet chairs. Between 1859 and 1930, GebrQder Thonet sold an unprecedented 50 million units of Model No. 14, (cafe chair) more than any other chair in the world up to that time5 (Figures 4.19, 4.20, and 4.21).

Originally designed for laminated wood production, the bentwood technique was utilized because sea travel and exposure to the elements during transportation caused delamination to occur. Steam bending required less work than laminating, and the chairs were more durable, given of the limitations of the glues available at the time. Using steam-bending techniques, the leg supports and seat back were made from solid beech wood and the seat frame was made from laminated wood. The seat pan was made from solid wood or

|

|

|

|

|

|

|

|

woven cane. Model No. 14 was an ideal cafe chair for the coffeehouses and cafes emerging throughout Europe and America. It was called the Vienna chair after the Viennese coffeehouses, where it first came into use. Coffeehouses were essential to Viennese social, intellectual, and artistic life, and the chair fit perfectly in this social and cultural context.

The beech wood was steamed at 100 degrees Celsius until pliable and then bent into shape using clamps and cast-iron forms for 20 hours. Craftsmen worked carefully together to manipulate the wood into the desired shape. The chair was transported in parts and assembled at the point of delivery from six pieces of wood and assembled together with ten screws and two nuts, eliminating complex joints. Model No. 14 is 35/ inches (90 cm) high, 16% inches (43 cm) wide, and 20% inches (52 cm) deep.6 It is elegant in its linear form and reductive in its shape. Lightweight and durable, its modest cost and flat-pack distribution made it an ideal choice for hospitality and residential use throughout the world (Figure 4.22). A crate measuring one cubic meter could hold 36 dismantled chairs.

It was one of the first pieces of furniture designed for all society rather than only for the wealthy. Conceived for mass production and flat-pack distribution, Model No. 14 was far ahead of its time in form and in the direct use of materials. It embodied and foreshadowed the ideals and spirit of modernism, which emerged nearly 70 years later. Model No. 14 is often cited as the flagship for the Thonet series of chairs. Due to the industrial production employed, Michael Thonet has been considered the world’s first industrial designer.

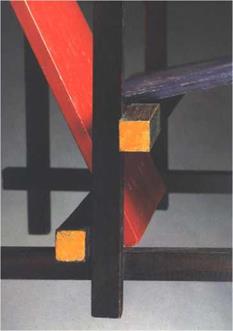

Gerrit T. Rietveld (1888-1965), along with Theo Van Doesburg (1883-1931) and Piet Mondrian (1872-1944), created the de Stijl movement and were dedicated to the creation of a universal aesthetic through the use of simple geometric forms and a color palette consisting of primary colors (red, yellow, and blue) as well as achromatic hues of black, white, and gray. "One can look for significant links between art and product design in any age, but at no time it has been closer than during the period of the Dutch movement de Stijl," wrote Ella Moody in 1966 in her book Modern Furniture.7 In the movement, space was defined by line, plane, and color.

The Red-Blue chair was based on standardized mass production ideals, originally fabricated in a natural oak, unpainted version in 1917, before Rietveld became a member of de Stijl. Rietveld considered its fabrication a social act, with the goal of mechanizing labor in order for the laborer to escape the boredom of hard, repetitive work (Figure 4.23). Six years later, Rietveld designed the Schroeder house (in Utrecht, the Netherlands), in which the Red-Blue chair appropriately fits.

The Red-Blue chair had a precedent.8 The original design was unpainted and had rectangular side panels. This "prototype" with rectangular side panels is at the Utrecht Centraal Museum and the London Victoria and Albert Museum. Furniture restorer Jurjen Creman documented measurements of the first chair, which are outlined here and graphically shown in Figure 4.24.

|

|

|

|

The process by which Rietveld fabricated this piece is an allegorical representation of the ideals behind its creation. He took a board of wood and sawed the middle part in two for the seat and backrest. The assembly of the chair is based on a 4-inch (10-cm) module, which is the thickness of three rails. The rails are doweled together. The seat and the back are mechanically attached to the frame with screws. Though the simple geometries and elements are clear, the mechanical systems are effectively hidden. The red 70-degree angled seat back and the blue 10-degree angled seat pan offer bodily support, and the black orthogonally positioned frame directs the loads to the ground through indirect transposition of forces. The frame is made of black-painted beech wood with yellow lacquered ends. The seat (blue) and back (red) are lacquered plywood. The chair is an abstraction of two systems—one composed of liberated, painted planes that support the body and the other a network of painted rails to support the painted planes. The Red-Blue chair is approximately 33.7 inches high; 25% inches deep; 34 inches wide (86.5 cm high; 66 cm deep; 83 cm wide) (Figure 4.25).

|

The Red-Blue chair is an expressive composition of form, space, and color. The black orthogonal components, combined with the intersecting, brightly colored planes, accurately represented the spirit of the age in the Netherlands (1918). The angle between the seat pan and seat back provides bodily comfort for rest, and even more significantly, the seat and back allow for body movement during use due to the flat painted planes. Within the social and formal context of the de Stijl movement, the design is effective and elegantly resolved (Figures 4.26 and 4.27).

|

|

|

Figure 4.26 Detail—seat back, seat pan, and support members. Photography by Jim Postell, 2006. |

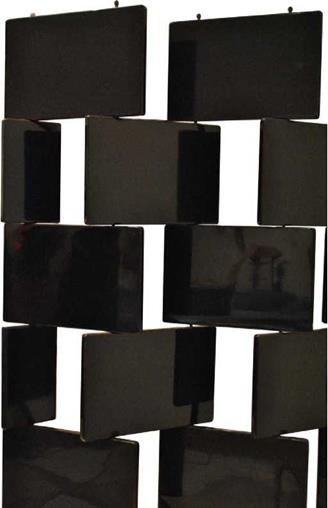

Fabricated first in white and then in high-gloss black polyester lacquered panels, Eileen Gray’s Blocs Screen expresses a transitional moment in her design career. The screen marked a shift from her early decorative and hand-lacquered works to her later work that incorporated industrial materials and industrial processes of fabrication. The lacquered Blocs Screen was first designed as part of a larger interior commission for Madame Mathieu-Levy’s apartment along the rue de Lota in Paris. The design evolved into several variations, each of which employed small lacquer-painted blocks to create a freestanding articulated screen.

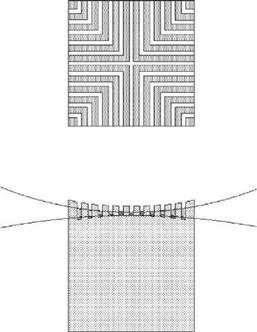

The Blocs Screen could be configured in a number of ways. The version presented in this study is four blocks wide and seven blocks high (other versions were five blocks wide and eight blocks high). The lacquered blocks in one screen could vary in size, proportion, and color from those in another screen. The lacquered modules illustrated in this study each have a square relief and are based on the Golden Section, which was used throughout the career of the architect Le Corbusier, with whom Eileen Gray apprenticed. The individual blocks are 10 inches high; 16.18 inches wide; % inch deep (25.4 cm high; 41.1 cm wide; 2 cm deep). The frame is held together with brass pins that support and mechanically enable the visual transparency of the screen. Overall screen dimensions are 741/2 inches high and 53/ inches wide (189 cm high and 136 cm wide) (Figures 4.28, 4.49, and 4.30).

The Blocs Screen could be configured in a number of ways. The version presented in this study is four blocks wide and seven blocks high (other versions were five blocks wide and eight blocks high). The lacquered blocks in one screen could vary in size, proportion, and color from those in another screen. The lacquered modules illustrated in this study each have a square relief and are based on the Golden Section, which was used throughout the career of the architect Le Corbusier, with whom Eileen Gray apprenticed. The individual blocks are 10 inches high; 16.18 inches wide; % inch deep (25.4 cm high; 41.1 cm wide; 2 cm deep). The frame is held together with brass pins that support and mechanically enable the visual transparency of the screen. Overall screen dimensions are 741/2 inches high and 53/ inches wide (189 cm high and 136 cm wide) (Figures 4.28, 4.49, and 4.30).

The beauty and appeal of the Blocs Screen lay in its conception and formal composition. The flexible array of individual pivoting panels creates

|

|

|

|

a simple, freestanding, and functioning screen that partitions space and extends the architectural quality of the surrounding walls. The screen was conceived as an interior accessory, as were many of Eileen Gray’s chairs, tables, carpets, and lighting designs, which furthered the notion of an integrated interior space composed of discrete, carefully arranged elements. The screen is visually attractive; however, it is relatively narrow in width and awkward to move about in space. It is a sculptural piece, composed of solids and voids. It is a screen to look at, not one to touch. The screen is playful as a receptor of light and is effective in partitioning space.

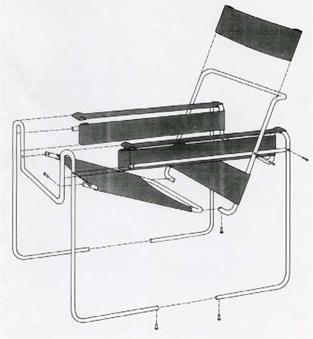

The Wassily club chair is an icon of the Modern Movement for its use of industrial materials and the clear expression of its fabrication (Figures 4.31 and 4.32). Designed by Marcel Breuer in 1925, the chair is still in production today. It was called the Wassily club chair because it was originally designed for the living room of Breuer’s friend Wassily Kandinsky, a renowned abstract painter and faculty member of the Bauhaus. Expressing the ideas behind the Wassily club chair, Breuer is quoted as having said:

I already had the concept of spanning the seat with fabric in tension as a substitute for thick upholstery. I also wanted a frame that would be resilient and elastic. The combination of elasticity and of members in tension would give comfort without bulkiness. I also wanted to achieve transparency of forms to attain both visual and physical lightness. Mass production and standardization had already made me interested in polished metal, in shiny and impeccable lines in space as new components for our interiors. I considered such polished and curved lines not only symbolic of our modern technology, but actually technology itself.9

This leap toward modern technology was intended for manufacture by Standard-Mobel, but the materials and process proved to be too costly. Today, Knoll International, a division

|

|

|

|

devoted to manufacturing classic twentieth-century furniture, produces the chair.

The chair is 28% inches high; 27Уг inches deep; 30% inches wide (73 cm high; 70 cm deep; 78 cm wide) (Figure 4.33). One might assume that the Wassily chair is heavy; however, it is light. The idea of using tubular metal was inspired by Breuer’s Adler bicycle, which he rode daily. The heavy cushioning of a comfortable chair has been replaced with tightly fitted, thick fabric (later becoming leather) held in tension around metal tubes. Breuer went to the Mannesmann steelworks for the manufactured bent steel. The chair is fabricated from standardized parts and can be easily disassembled (Figure 4.34).

The Wassily club chair is inventive in its use of new technology and aesthetically pleasing. Breuer wrote:

Two years ago, when I saw the finished version of my first steel club armchair, I thought that this out of all my work would bring me the most criticism. It is my most extreme work both in its outward appearance and in the use of materials; it is the least artistic, the most logical, the least cozy and the most mechanical.10

The Wassily club chair is a simple and graceful design. Due to the relatively flat leather planes and the generous space in which to sit, it allows users to move about freely (Figure 4.35).

The Wassily club chair inspired many chair designers throughout the twentieth century. It has been hailed by critics as one of the greatest chairs of the twentieth century, but there are those who disagree. For some critics, it is problematic in its fixed posture, the backward angle of the seat back to the seat pan, and its tactile quality. These aspects limit its utility. This raises the question, what qualities constitute a great chair in the twentieth century?

The Wassily club chair inspired many chair designers throughout the twentieth century. It has been hailed by critics as one of the greatest chairs of the twentieth century, but there are those who disagree. For some critics, it is problematic in its fixed posture, the backward angle of the seat back to the seat pan, and its tactile quality. These aspects limit its utility. This raises the question, what qualities constitute a great chair in the twentieth century?

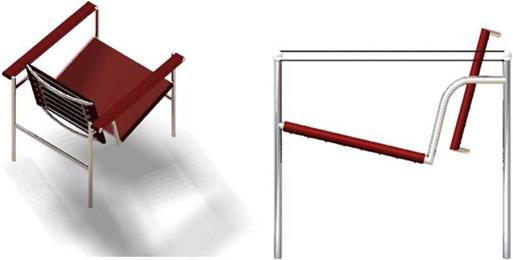

|

Le Corbusier designed functional furniture that utilized new materials and industrial modes of production. Charlotte Perriand joined Le Corbusier’s atelier in 1927 and contributed to the design, as did Pierre Jeanneret. Le Corbusier established the parameters for the furniture, but it was left up to Perriand and Jeanneret to resolve and detail the design. Conceived as a machine for sitting, the Basculant chair can accommodate numerous postures. it is Perriand who has been credited with the seat back’s mobility and the use of tubular steel. The Basculant chair was created for "living room conversation" for a French villa in Ville d’Avray and, ultimately, for mass production (Figures 4.36 and 4.37).

The Basculant chair, inspired by the British army officer’s Pel chair designed by F. M. Allen Roorkhee, was initially refused production by Peugeot’s bicycle-making section. Le Corbusier then made an arrangement with Thonet to produce the chair in 1929. Despite the availability of the new technology of tubular metal, the chair was produced in wood and rush materials for a Brussels exhibit in 1935 (Figures 4.38, 4.39, and 4.40).

The Basculant chair, inspired by the British army officer’s Pel chair designed by F. M. Allen Roorkhee, was initially refused production by Peugeot’s bicycle-making section. Le Corbusier then made an arrangement with Thonet to produce the chair in 1929. Despite the availability of the new technology of tubular metal, the chair was produced in wood and rush materials for a Brussels exhibit in 1935 (Figures 4.38, 4.39, and 4.40).

|

|

L

L

Figure 4.38 Siege a Dossier Basculant B301, front view. Photography by Jim Postell, 2011. Computer model by Nora L. Bauser.

|

The chair is 25% inches high; 23% inches wide; 25% inches deep (64 cm high; 59.7 cm wide; 64.8 cm deep). It weighs 29 lb. Today, it is available in different upholstery and metal finishes. The sling-back chair, as it is sometimes referred to, has a steel frame finished in either chrome or matte black. In 1929, it was fabricated of polished nickel-plated steel tubing to reduce the cost. Today, Cassina offers the chair in pony hide with black leather arms, Russian red saddle leather with matching arms, or black saddle leather (Figure 4.41).

The structure consists of an assemblage of metal sections, none of which forms a closed framework except for the chair’s back. Both the front and rear elevations consist of an H design composed of two vertical supports and one horizontal support. The structure and stability of the chair rely entirely on the welded connections of the joints, which differ from the bolted connections of other Bauhaus pieces. The seat pan consists of a stretched material over thin tubing with supporting springs underneath. The chair’s back is similar to the seat pan, with the material held in tension by springs. The arms of the chair provide no structural support, and the leather straps freely rotate around the projecting ends of metal tubes.

The desire to create an affordable chair and to employ industrial materials and new technologies drove the design, yet the chair remains expensive to produce because of its details. Nonetheless, the chair is important as a model introducing the impact that female designers of the Bauhaus had in creating aesthetically pleasing, comfortable, and practical furniture designs.

The desire to create an affordable chair and to employ industrial materials and new technologies drove the design, yet the chair remains expensive to produce because of its details. Nonetheless, the chair is important as a model introducing the impact that female designers of the Bauhaus had in creating aesthetically pleasing, comfortable, and practical furniture designs.

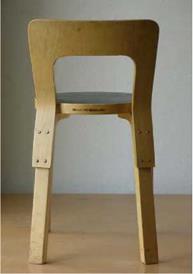

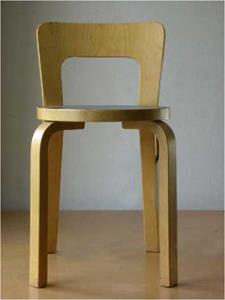

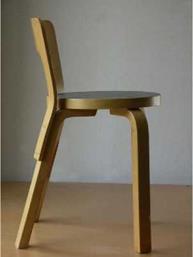

In the 1920s, Alvar Aalto began experimenting with bent and laminated wood. He was, in his own words, immersed in his "struggle against metal in furniture design." When he moved to Turku, Finland, in 1927 and teamed up with the factory owner Otto Korhonen, they perfected one of Aalto’s most important discoveries in furniture design: the bent knee technique that is used in making the legs of Stool 60 (Figures 4.42, 4.43, 4.44, and 4.45). The bent knee, stacking stool with three legs was first introduced to the public at the 1933 London Exhibition and originally designed by Aalto for the Viipuri town library.

It has been said that as Aalto and Korhonen were throwing the working prototype around the factory floor in order to test its durability, Aalto exclaimed, "This stool is going to be made in the thousands!" Within 50 years, more than a million stacking stools were in existence. The stool became the most widely sold piece of Alvar Aalto’s furniture and represents a turning point in Aalto’s design work.

The legs of the stool are made of bent birch wood, utilizing special cutting and joining technologies, while the seat is available in either black or red linoleum, white, yellow, red, or blue laminate with a thin birch band, or foam covered and upholstered to specification.

Birch wood was readily available from local suppliers, but it was not good for bending and fractured easily. Aalto’s idea was to take a solid piece of birch wood and saw it open on one end in the direction of the grain. Next, thin pieces of wood were glued into the grooves. This allowed the wood to be bent to the desired radius and angle, which in the case of Stool 60 was slightly less than 90 degrees. As the wood dried, it straightened to a

|

|

|

|

|

90-degree angle and could be screwed directly into metal inserts placed in the bottom of the seat pan. The use of heat to bend the wood demanded fast-setting glue, and it was not until the 1960s that the legs could be bent mechanically. The stool is 171/e inches high and 13% inches in diameter (43.5 cm high and 34.9 cm in diameter). Various heights and finishes are available. The stool can be purchased as a three – or four-legged stool. Stool 65 is a modified four-legged version with back (Figures 4.46, 4.47, and 4.48).

Korhonen’s factory fabricated most of Aalto’s furniture until the 1940s. After World War II, Eggers in Wisconsin produced Aalto’s furniture in the United States, with sales out of New York.

Today, the Finnish company Artek produces Stool 60. It is shipped flat-packed. Stool 60 is designed and crafted as a simple but elegant, modern yet traditional stool—all at the same time.

|

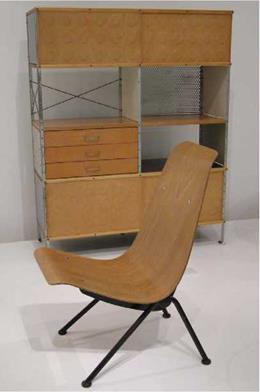

The Eames Storage Unit (ESU) was a popular but short-lived storage system developed by Charles and Ray Eames between 1949 and 1950. In 1940, Charles Eames and Eero Saarinen

|

worked on a system of cabinets. The units could be used as benches, as shelves or for storage. Four years later, Charles and Ray Eames developed the Case Goods series, which were displayed at the Museum of Modern Art (MOMA) in New York City in 1946. Inspired by the metal knock-down shelving units that people bought for use in their garages and basements, Charles and Ray Eames developed a new system for an exhibit entitled Design for Living. The idea of an inexpensive, lightweight, functional system was important in the design. In 1950, Herman Miller marketed the ESU. Originally flat-packed, and requiring only a screwdriver and wrench to put together, the ESU did not sell well, so Herman Miller began making preassembled units. In this approach, dents and scratches proved to be problematic during distribution. As a result, the applied supports were set flush with the wood shelves. In 1955, Herman Miller stopped production of the ESU due to slow demand. Recently, with the renewed interest in the work of Charles and Ray Eames, Herman Miller has brought the ESU back into production (Figures 4.49 and 4.50).

The ESU is a kit of standardized parts.

The uprights, cross-bracing, and perforated metal backs are all zinc-coated galvanized steel. The legs have a nylon glide at their base. The cabinet doors are dimpled and laminated plywood. The shelves and drawer fronts are plywood. All of the plywood comes with a birch or walnut veneer on the exposed faces, while their side and bottom edges incorporate lacquered Masonite panels. The ESU is available in four sizes. The smallest is 24/ inches wide; 20/ inches high; 16 inches deep (62.2 cm wide; 52.1 cm high; 40.6 cm deep). The second unit is 47/ inches wide; 20/ inches high;16 inches deep Figure 4.51 Computer model, ESU. Computer model by the author and Nora L. Bauser.

The uprights, cross-bracing, and perforated metal backs are all zinc-coated galvanized steel. The legs have a nylon glide at their base. The cabinet doors are dimpled and laminated plywood. The shelves and drawer fronts are plywood. All of the plywood comes with a birch or walnut veneer on the exposed faces, while their side and bottom edges incorporate lacquered Masonite panels. The ESU is available in four sizes. The smallest is 24/ inches wide; 20/ inches high; 16 inches deep (62.2 cm wide; 52.1 cm high; 40.6 cm deep). The second unit is 47/ inches wide; 20/ inches high;16 inches deep Figure 4.51 Computer model, ESU. Computer model by the author and Nora L. Bauser.

(120.7 cm wide; 52.1 cm high; 40.6 cm deep). All variations allow an arrangement of panels, cross-bracing, and shelves (Figure 4.51).

|

The design expresses honesty in form and function. Fabrication and material selection are straightforward. The ESU foreshadowed the design of Charles and Ray Eames’s home in Southern California, known as the Eames House. The ESU is significant in its economy, modularity, and ready-to-assemble fabrication. It has inspired many designers and architects since its conception in 1950 (Figure 4.52).

Jean ProuvE (1901-1984) worked with industrial materials throughout his career as a designer in Nancy, France. For him, the nature of laminated Baltic birch, painted steel, aluminum, and rubber was in line with the mechanization and industrialization of the early twentieth century (Figure 4.53). Prouve’s work captured the spirit of the times through his use of industrial materials and the handcrafted approach in fabricating his working prototypes (Figure 4.54).

The Antony chair is characterized by its hand-welded and black-painted steel finish, expressive use of hardware, and mechanical connections juxtaposing the gracefully laminated birch compound seat (Figures 4.55, 4.56, and 4.57). The bent and painted tubular

|

|

|

|

metal, flat steel supports, and the "pivotal" large-diameter steel tube running horizontally below the seat shell, along with the expression of the chair’s hardware and overall form, have inspired many furniture designers. The primary feature of the Antony chair is the 3/8-inch (1-cm) thick molded plywood body support that serves as the seat pan and seat back in one shell. The molded plywood body support is a compound curve. In 1950, this was a remarkable accomplishment due to the complexity of the form and the tendency for veneers to split when simultaneously stressed in two or more directions.

|

|

|

|

|

|

Harry Bertoia achieved a synthesis of sculpture and function with his series of wire-framed chairs. These chairs were, in his words, "studies in space, form, and metal."11 In terms of functionality, he thought that if a chair were used for an extended period of time, it should accommodate the movements of the human body in order to remain comfortable. That is what led him to use thin metal rods, thinking that they would adjust and respond to the body’s movement (Figures 4.58 and 4.59).

The Wire side chair is a grid of steel wires, approximately 3/16 inch (5 mm) in diameter, bent and welded to form a graceful, compound curved, and unified seat and back support. The seat and back form is composed atop a base of two steel rods, approximately У2 inch (1.25 cm) in diameter each, bent and welded. The entire chair is 29Уг inches high; 21% inches wide; 23% inches deep (74 cm high; 53.9 cm wide; 58.7 cm deep).

The production process, although now common, was revolutionary at the time of the chair’s initial production. A wooden mold was first created, in which all of the wires were bent in place by hand. It was easier to bend the rods by hand than by machine. Once all the wires were properly arranged, an electric current was applied to the steel, which welded every connection simultaneously. The final assembly was either given a chrome finish or

|

|

|

|

coated with rilsan, an applied vinyl finish. Rilsan was applied by using a fluid-bed process in which the steel chair was heated and then passed through a chamber containing suspended vinyl particles. The heated steel caused the vinyl to melt and adhere to the steel in an even coating, which resulted in a durable finish. A seat cushion made of a padded fabric, vinyl or leather could be fastened to the seat (Figure 4.60).

The Wire side chair is exceptionally comfortable. The steel rods bend just enough to mold to a range of human body shapes and a range of positions, yet remain stiff enough to provide appropriate support. The side chair works well in group settings, within courtyard and public gathering areas, alone, or at a desk. Flaws in its stability are apparent in that it tends to tip forward when one stands up and can lean forward while one remains sitting.

The success of the Wire side chair resulted in several wire chair variations. The upholstered side chair, the Diamond chair, the Bertoia Bird chair, and Bertoia Asymmetric chaise— all available in a range of color fabrics (Figure 4.61).

|

|

|

|

|

After 10 years of research and observations of office work, Herman Miller introduced Action Office® in 1968, the first panel-based, open-plan office system in the world.12 The designer, Robert Propst, developed a system of panels and components that could be configured and reconfigured to respond to needs that would develop over time. Panels were available in a variety of heights, widths, and surface treatments. Components, including work surfaces and storage units, attach in 1-inch (2.5-cm) height increments, giving flexibility to the assembly and allowing users to work comfortably. As with most office systems, the ability of individuals to control their physical and ambient work environments was paramount.

Action Office marked a departure from the previous era’s assumptions of what office furniture should be. The Action Office system transformed the workplace, as well as Herman Miller and the entire furniture industry, into a systems-approach business led by design (Figures 4.62 and 4.63).

Action Office Series 2 reestablished the success of the original system by expressing the basic Action Office concept with new details and extended capabilities. The revised panels carried increased energy and cable loads to meet heavy technological demands. Work surfaces and storage components responded to changing aesthetic tastes. A number of new components offered options to suit each individual’s work process. Action Office Series 2 remained true to the fundamental principles of the original system: space-saving benefits, simple ordering and inventory, design options, and interchangeable components (Figure 4.64).

Figure 4.62 Action Office, C & S Bank, showing vertical storage on three-way panels amid offices, designed by Robert Propst for Herman Miller, 1968. Photography courtesy of Herman Miller, Inc.

Figure 4.62 Action Office, C & S Bank, showing vertical storage on three-way panels amid offices, designed by Robert Propst for Herman Miller, 1968. Photography courtesy of Herman Miller, Inc.

|

|

|

Figure 4.65 Action Office Series 2 with curved work surface and panels. Photography by Steve Hall/ Hendich Blessing. Courtesy of Herman Miller.

Figure 4.65 Action Office Series 2 with curved work surface and panels. Photography by Steve Hall/ Hendich Blessing. Courtesy of Herman Miller.

Action Office is easy and quick to install and reconfigure. It is a systems-based product, a kit of parts allowing the user to configure and compose various components as desired. With over a $4 billion installed base, the Action Office system is a remarkable concept that has transformed both an industry and the office workplace (Figure 4.65).

|

|

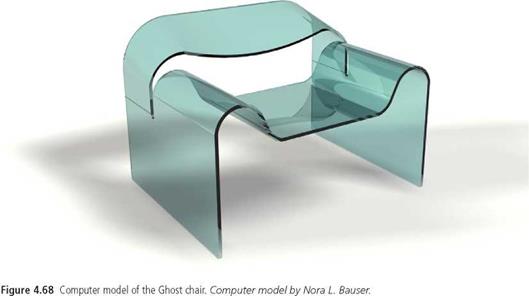

The stated philosophy of the Italian glass furniture company Fiam is to produce works that "free glass from its historical role of ornamental accessory and make glass a protagonist in furnishing, resulting in an unobtrusive and important presence in people’s lives." Located in the heart of Brianza in northern Italy, Fiam is renowned for producing glass furniture. Fiam hires top designers such as Cini Boeri, Philippe Stark, and Danny Lane to realize their ideas. The Ghost chair is an important piece for Fiam and for furniture design in general. It is considered to be the first successful fabrication of an all-glass chair without adhesives or mechanical connections. It is constructed from a single sheet of 12-mm crystal and is reported to be stackable (two high) (Figures 4.66 and 4.67).

|

|

The ability to fabricate the Ghost chair resulted from a revolutionary type of glass called float glass, which was developed in the 1960s by Pilkington, an English furnishing producer. The term refers to the flat, perfectly smooth sheets of glass, which are produced by causing magma to oscillate on a bed of molten tin. But Fiam takes this process further in order to produce furniture designs in glass. The fabrication process begins by taking a piece of float glass and cutting out a single oval shape using the high-precision Paser system (high-pressure water spray mixed with an abrasive powder), with the remaining portion forming the seat, back, and armrests. Inside a curving chamber, the glass is heated and reaches the maximum level of thermal stress. At approximately 700 degrees Celsius, the glass can be molded like wet clay—stretched over a chair mold by the force of gravity.12 Patented technologies applied during the cooling stage and the absence of residual stress allow the glass to become exceptionally strong. The chair weighs 79 lb and can carry a load of 300 lb. The chair is 26% inches high; 37Уг inches wide; 29Уг inches deep (67.8 cm high; 95.3 cm wide; 74 cm deep). It consists of a single sheet of Уг-inch (1.25 cm) crystal glass that is folded and cut during the process on a computer numeric control device (CNC machine) and moved by an applied force of air (Figure 4.68).

The Ghost chair is intriguing because the designers use and express the full potential of glass as a weight-bearing material and as an aesthetic medium. Although the use of glass in design often conjures up rigid, boxlike interpretations, this chair has a relaxed air in the compound curves that form the arms and back rest. Although it is proportioned to be comfortable as a device for sitting, one can’t quite imagine the user feeling fully relaxed in a glass chair for both thermal and psychological reasons. These reactions may be due to the limitations of human imagination rather than the limitations of the design itself; however, glass does feel cool to the touch. Nevertheless, in this context, comfort was not the primary reason for its production.

The laminated, hard white maple chair series was initially inspired by bushel baskets. The Cross Check armchair is one of a series of comfortable bentwood chairs, each given a name based on hockey terms: Power Play armchair, Hat Trick side chair, and Face Off table (Figure 4.69). The supports and the chair’s seat are formed from the same lightweight, slender wood strips. The laminated plywood strips create a single coherent form. Frank Gehry explored the possibility of bentwood through many working prototypes and proved it to be pliable, with "spring" and lightweight effectiveness. The Cross Check chair is one of the last chair designs developed in Gehry’s bentwood series.

The primary intent was to develop a diagonally woven chair. Gehry accomplished this by taking loose strips of bentwood and working the material into expressive form. The first prototype was achieved in 1990. The second prototype became the first diagonally woven chair that was structurally stable, and this opened the door for the development of the final Cross Check chair.

To improve the back support, the arms were brought forward and attached to the front of the chair. This brought the chair into balance while simultaneously softening the geometric angularity of earlier triangulated bases. The new arm design suggested providing another leg, which was further integrated into the final design of the chair in addition

|

Figure 4.69 Laminated maple chairs and tables inspired by the woven construction of bushel baskets. Designed by Frank O. Gehry (1992) for Knoll, Inc. Photography courtesy of Knoll, Inc. |

to the second over-arm. In keeping with the curvilinear theme, the back slats extend to loop over, which strengthen the final design. Knoll developed an environmentally sound, water-based dip-finishing system to seal and finish the chair.

The chair is made from maple veneers harvested from sustainable forests and cut into 2-inch (5-cm) wide, 1/32-inch (0.7-mm) thick strips. It is laminated to six-, seven-, and eight-ply thickness using high – bond urea glue, with all wood grain running in the same direction for resilience. Thermoset glue provides structural rigidity, minimizing the need for metal connectors while allowing for ergonomic movement and flexibility. The backs of all chairs flex for added comfort. No glues are used in the seat assembly to allow flexibility in unison with springlike movement. The Figure 4.70 Cross Check armchair, front oblique view. Photography courtesy

The chair is made from maple veneers harvested from sustainable forests and cut into 2-inch (5-cm) wide, 1/32-inch (0.7-mm) thick strips. It is laminated to six-, seven-, and eight-ply thickness using high – bond urea glue, with all wood grain running in the same direction for resilience. Thermoset glue provides structural rigidity, minimizing the need for metal connectors while allowing for ergonomic movement and flexibility. The backs of all chairs flex for added comfort. No glues are used in the seat assembly to allow flexibility in unison with springlike movement. The Figure 4.70 Cross Check armchair, front oblique view. Photography courtesy

total weight of the chair is 12 lb. The seat height is of Knoll, Inc.

181/g inches; 28 inches wide; 335/g inches arm height;

181/g inches; 28 inches wide; 335/g inches arm height;

281/г inches wide; 24 inches deep (46 cm seat height;

71.1 cm wide; 84 cm arm height; 72.4 cm wide;

61 cm deep) (Figure 4.70).

|

|

The design process was a successful collaboration between Gehry’s studio and Knoll International. The Cross Check chair is a high-quality chair that in production rekindles many notions of the Industrial Revolution and the craft trades of the nineteenth century. The design of the Cross Check chair provides an exciting sitting experience and infuses artistic sensitivity with structural and technological innovation (Figures 4.71,4.72, and 4.73).

|

Figure 4.72 Computer model—side view. Computer rendering by Nora L. Bauser |

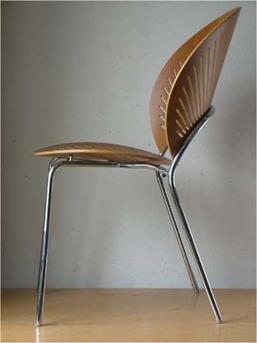

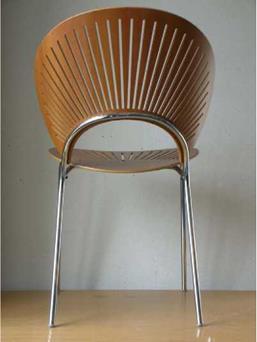

Nanna Ditzel was born in Copenhagen in 1923. She began her work in furniture design through cabinet making before attending the Industrial Arts and Crafts College and the Royal Academy of Fine Arts in Copenhagen. Following World War II, she was one of the very few women working in furniture design. The Trinidad chair is a lightweight, comfortable, stackable cafe chair. Inspiration for the design came from a time in Nanna’s life when she lived in the Caribbean islands and developed an interest in colonial-style wooden architecture and associated "fret-saw" designs known affectionately as "Gingerbread." The chair’s name comes from the country of Trinidad, whose traditional fretwork techniques inspired Ditzel (Figure 4.74).

The Trinidad chair is available in laminated maple, beech, cherry, teak, or lacquer-painted wood and can be purchased with or without arms. A high-density foam seat-cushioned model is also available. The chair’s seat and back are supported by a metal tubular frame. The fabrication process involves laminating several sheets of wood, applying a veneer, and cutting the overall shape and flexible slits. The wooden back and seat pan are attached to the metal frame with metal fasteners located along the bottom and back of the chair. Synthetic rubber footings are placed on the ends of the four legs. The chair weighs 22 lb and is 19% inches wide; 22Уг inches deep; 32% high; with a seat height of 17Уг inches (50 cm wide; 57 cm deep; 83 cm high; 44 cm seat height) (Figure 4.75).

![]()

|

|

|

|

|

|

The design is elegant and the proportions are graceful. The design won the APEX Award first prize in 1997, and the following year it won the Danish Industrial Design Award (Figures 4.76, 4.77, and 4.78).

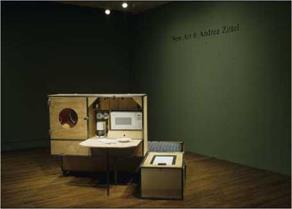

Andrea Zittel is an artist who uses her own day-to-day living as the impetus for her artwork. The A-Z Living Units were a series of fabrications (hybrids between furniture and shelter fabrications) designed to change one’s sense of personal space. The various designs left no area of daily living, no matter how basic, untouched. The initial Living Units were conceived and fabricated in the early 1990s, when Zittel was living in New York.13 The images of the A-Z Living Units were taken from an installation at the Cincinnati Museum of Art entitled "New Art 6" (1995). The materials were kept to a simple kit of parts, including angle iron, Baltic birch plywood, hardware, and upholstery. As the fabrications sold and began to be used, the designs began to be modified by their new owners. Nonetheless, the structural framework and transformative nature of the fabrications remained intact (Figures 4.79, 4.80, and 4.81).

In discussing her work, Zittel explains:

I lived in contained spaces that weren’t mine. I wanted to create a highly personalized space. It was like owning a house that would fit inside a shell within a house other people owned. I would do all the modifications within the capsule of the Living Unit. That series ended when I bought a building in New York in 1994.14

Several versions of the pit bed were made. The pit bed is an assembly referred to as the Comfort Unit in the Living Units series. Some versions were exact copies and others were radical take-offs. But at the core of the various fabrications in the Living Units series such as the pit bed is an idea of a solution designed to satisfy the conflicting needs for security, stability, freedom, and autonomy. Owning a Living Unit created the security and permanence

|

|

|

|

|

|

|

|

|

of a home, which would then be set up inside the homes that other people owned. It provided freedom because whenever the owners wanted to move, they could collapse the unit and move it to a new location. The Living Units were remarkably simple social constructions, transformable and functional spaces in which to live (Figures 4.82 and 4.83).

Don Chadwick and Bill Stumpf designed the Aeron chair in 1994 for Herman Miller. The design is significant because the chair was made from 80 percent recycled materials and was remarkably ergonomic. The transparency of the chair as a visual element was in keeping with the idea of transparent architecture and technology. Transparency is the effort to make technology less opaque, to communicate the inner workings of things, and to make objects less intrusive on the environment (Figures 4.84 and 4.85).

The design team conducted anthropometric studies, using a specifically developed instrument to calculate average dimensions ranging from popliteal height to forearm length. The team did pressure mapping and thermal testing to determine the weight distribution and heat – and moisture-dissipating qualities of the semitransparent pellicle suspension mesh made of polyester and Lycra on the chair’s seat and back.15 The transparent material allows air to pass through, adding to long-term comfort by preventing body-heat buildup. Field studies examined the relationship between the sizes of people and their preference for chair size.

|

Figure 4.84 Aeron chair, designed by Don Chadwick and Bill Stumpf (1994) Figure 4.85 Aeron chair-side view. Photography, courtesy of for Herman Miller—front view. Photography, courtesy of Herman Miller. Herman Miller. |

The unique form of the Aeron chair expresses its purpose and use, as well as the material composition of its parts and the way they connect.

The slightly translucent and reflective nature of its surfaces gives it an airy quality. The Aeron chair becomes part of the person who uses it and the environment that surrounds it (Figure 4.86). A contoured molded polyurethane foam pad can be adjusted vertically through a 4^-inch height range. Its depth can be set at % inch or 1% inches, useful in changing the depth of the lumbar support. Four pivot points in the movement mechanism of the Aeron chair advance the seat recline that the designers achieved in both the Ergon (1976) and Equa (1984) chairs. The tilt-tension adjustment lets the user easily control the resistance felt when leaning back.

The slightly translucent and reflective nature of its surfaces gives it an airy quality. The Aeron chair becomes part of the person who uses it and the environment that surrounds it (Figure 4.86). A contoured molded polyurethane foam pad can be adjusted vertically through a 4^-inch height range. Its depth can be set at % inch or 1% inches, useful in changing the depth of the lumbar support. Four pivot points in the movement mechanism of the Aeron chair advance the seat recline that the designers achieved in both the Ergon (1976) and Equa (1984) chairs. The tilt-tension adjustment lets the user easily control the resistance felt when leaning back.

The chair functions well in the workplace, where there are many different multifunctional tasks to perform over extended periods of time.

|

The material feels cool but not cold, making the haptic experience inviting and comfortable. The woven pellicle material offers appropriate support. Depending on the weight and size of the user, the Aeron chair can be purchased in one of three sizes, from A (small) to C (large) (Figure 4.87), thereby ensuring greater comfort for the user.

The background for this particular design (Figures 4.88, 4.89, and 4.90) is a sad one; however, it is important to understand in order to comprehend the significance of the work. Designer Erik Skoven tells the story:

"A 26-year-old Danish woman, pregnant with her second child, is found to have leukemia. A choice is to be made and the baby is taken by caesarian after which the mother receives full chemotherapy—and dies. The child, now two years old, lives with the father and thrives. The grief of the family members was deep and the thought of designing something for them to sit on at the grave came to the designer. Something simple and yet beautiful: a sitting block of wood that would last for a long time, and yet disintegrate years from now, when perhaps the memories of Therese begin to fade.”16

The outdoor wooden stool was conceived and fabricated in a meaningful way during a difficult time of grieving the loss of family (Figure 4.91). Erik Skoven describes an underlining theme for the wooden stool in a brief poem:

With knots and cracks, like our love

No empty and hollow spaces

|

|

|

|