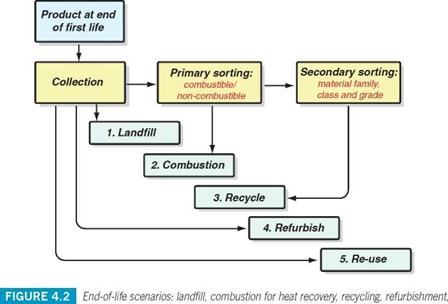

Figure 4.1 introduces the options: landfill, combustion for heat recovery, recycling, reengineering, and reuse.

Landfill. Many of the products we now reject are committed to landfill. Already there is a problem; the land available to "fill" in this way is already, in some European countries, almost full. Recall one of the results discussed in Chapter 2: if the consumption of materials grows by 3% per year, we will use and, if we discard it, throw away as much "stuff" in the next 25 years as in the entire history of industrialization. Landfill is not going to absorb that. Governmental administrations react by charging a landfill tax— currently somewhere near €50 per tonne and rising, seeking to divert waste into the other channels of Figure 4.1. These must be capable of absorbing the increase. None, at present, can.

Combustion for heat recovery. Materials, we know, contain energy. Rather than throwing them away, it would seem better to retrieve and reuse some of this energy by controlled combustion, capturing the heat. But this is not as easy as it sounds. First there is the need for a primary sorting to separate combustible from noncombustible material (see Figure 4.2). Then the combustion must be carried out under conditions that do not generate toxic fumes or residues, requiring high temperatures, sophisticated control, and expensive equipment. The energy recovery is imperfect partly because it is

|

and reuse. Different levels of sorting and cleaning are required for each. |

incomplete and partly because the incoming waste carries a moisture content that has to be boiled off. The efficiency of heat recovery from the combustion process is at best 50%, and if the recovered heat is used to generate electricity, it falls to 35%. And communities don’t like an incinerator at their back door. Thus useful energy can be recovered by the combustion of waste, but the efficiency is low, the economics are unattractive, and the neighbors can be difficult.

Despite all this, combustion for heat recovery is in some circumstances practical and attractive. The most striking example is the cement industry, one that has an enormous energy budget (and CO2 burden) because of the inescapable step of calcining in its production. Increasingly, combustion of vehicle tires and industrial and agricultural wastes are used as a heat source, reducing the demand on primary fuels, but not, of course, the attendant CO2.

Recycling. Waste is only waste if nothing can be done to make it useful. It can also be a resource. Recycling is the reprocessing of recovered materials at the end of product life, returning them into the use stream. It is the end-of-life scenario that is best adapted to extracting value from the waste stream. We return to this topic in Section 4.5 for a closer look.

Reengineering or reconditioning. There is the story of the axe—an excellent axe—that, over time, had two new heads and three new handles. But it was still the same axe. Refurbishment, for some products, is cost effective and, compared with total replacement, energy efficient. Aircraft, for instance, don’t wear out; instead, replacement of critical parts at regular inspection periods keeps a plane, like the axe, functioning just as it did when it was new. The Douglas DC-3, a 60-year-old design, is still flying, though not of course in the hands of its original owner. Premium airlines fly premium aircraft, so older models are sold on to operators with smaller budgets.

Reengineering is the refurbishment or upgrading of the product or of recoverable components. Certain criteria must be met to make it practical. One is that the design of the product is fixed, as it is with aircraft once an airworthiness certificate is issued, or that the technology on which it is based is evolving so slowly that there remains a market for the restored product. Some examples are housing, office space, and road and rail infrastructure; these are sectors with enormous appetites for materials. Some more examples: office equipment, particularly printing equipment and copying machines, and communication systems. These are services; the product providing them is unimportant to those who need the service, so long as it works well. It makes more sense to lease a service (as we all do with telephone lines, mobile phones, Internet service provision, and much else) because it is in the leasers’ interests to maximize the life of the equipment.

And that is the other obstacle (together with rapidly changing technology) to refurbishment: that fashion, style, and perceptions change, making a refurbished product unacceptable, even though it works perfectly well. Personal image, satisfaction—even self-respect are powerful drivers.

Reuse. The cathedrals of Europe, almost all of them, are built on the foundations of earlier structures, often from the 10 th or 11th century—built, in turn, on a still earlier 5th – or 6th-century beginning. If in a region that was once part of the Roman Empire, columns, friezes, fragments of the forum, and other structural elements of yet greater antiquity find their way into the structure, too. Reuse is not a new idea, but it is a good one.

Put more formally: reuse is the redistribution of the product to a consumer sector that is willing to accept it in its used state, perhaps to use for its original purpose (a secondhand car, for instance), perhaps to adapt to another (converting the car to a hot-rod or a bus into a mobile home).[12] That is a question of communication. Housing estate listings and used car and boat magazines exist precisely to provide channels of communication. Charity shops acquire clothing, objects, and junk[13] from those for whom they had become waste, and sell them on to others who perceive them to have value. And here’s a thought: the most effective tool ever devised to promote reuse is probably eBay. com, successful in this task precisely because it provides a global channel of communication.