|

|

|

|

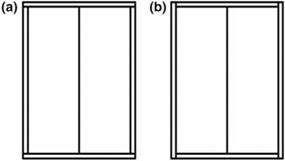

The characteristics of form and construction of the furniture piece are determined on the basis of spatial organisation of form, interconnection of main structural components and architectural structure of the product. Depending on the spatial organisation of the form, i. e. from the spatial distribution of individual elements of the furniture piece, three basic schemes of furniture can be distinguished (Fig. 2.9):

Fig. 2.9 Spatial organisation of the form of the furniture piece: a with an open spatial structure, b with a partially open spatial structure, c with a volume spatial structure

• with an open spatial structure, in which linear and surface elements dominate,

• with a partially open spatial structure, in which linear, surface and volume elements can dominate and

• with a volume spatial structure, in which volume elements dominate with small participation of linear and surface elements.

In furniture with a volume spatial structure, an additional feature can be distinguished—modularity. This feature of furniture increases functionality, many variants of use, as well as quality of the designed and furnished interiors. Modular furniture is designed on the basis of a body with a universal structure of elements, which maintains unified and repetitive closed dimensions in universal templates, with the possibility of any completion and decompletion of the system. Completion of systems can be done vertically, horizontally and matrixwise by using a system of simple connections between the elementary solids of furniture. Depending on the design, modular furniture can be divided into (Fig. 2.10):

• single-bodied,

• multi-bodied,

• universal for completion,

• on a frame and

•

|

|

for hanging.

Due to the method of binding certain structural components, subassemblages and assemblages, furniture can be divided into:

• non-disassembling, produced in the form of compact blocks, which makes their disassembly impossible,

• disassembling, produced in the form of solids that provide the possibility of repeatable disassembly and reassembly and

• for individual assembly, sold in packages containing elements for repeatable assembly and disassembly.

Taking into account the characteristics arising from the design of the furniture, two main groups can be distinguished:

• case and

• skeletal.

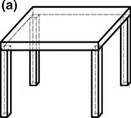

Case furniture is built mainly from panel elements, in which thickness is several times smaller than the other dimensions. Typically, these elements are located relative to each other in such a way that closes space from five or six sides. Depending on the relative positions of the external elements of the furniture piece’s body, two subgroups of case furniture have been distinguished (Fig. 2.11):

• flange, in which the top and bottom of the furniture piece (called flanges) are placed from the top and the bottom on the side walls. In this case, the upper element is called the top flange and the bottom element, the bottom flange. Such a piece of furniture can be supported on legs, a frame or a socle,

• rack, which are characterised by the fact that the top and bottom of the furniture piece can be found between the side walls. In this case, the structural solutions for the base part are as follows: the furniture piece can be supported on legs, a frame, socle, or on extensions of the side walls to the bottom, which are called racks.

|

Fig. 2.11 The division of case furniture depending on the relative positions of the sides, and top and bottom of the furniture piece: a flange, b rack |

|

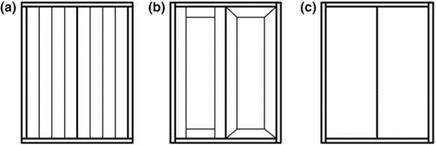

Fig. 2.12 The division of case furniture depending on the design of visible parts: a slat, b frame panel, c board |

|

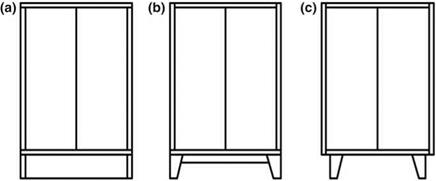

Fig. 2.13 Body of furniture placed on a socle, b frame, c legs |

Due to the nature of the structure, visible parts or external elements, case furniture is divided into (Fig. 2.12):

• slat,

• frame panel and

• board.

Given the solutions of designing support construction of case furniture, bases are distinguished in the form of a socle, a frame and legs (Fig. 2.13).

Depending on the construction and the technological characteristics, the following furniture is distinguished:

• segment, in which structure, external dimensions and functionality allow their vertical or horizontal configuration and

• compact, built from elements of unified dimensions and construction solutions that enable folding any suites of different purposes and dimensions.

Case furniture can be single – or multifunctional, which enables to use them in different ways, for example:

• a wardrobe, a tall case furniture piece designed primarily to store clothing, bedlinen, office binders, folders, drawings, etc.,

• library bookcase, a cupboard with shelves and mostly glass doors designed to store books,

• bookcase, a furniture piece consisting of a few or a dozen or so shelves hung on the side walls, with or without a rear wall, open or partially closed,

• glass case, glass cupboard or top part of a dresser, for storing decorative ceramics, dishes and jewellery,

• dresser, serves to store dishes, table linen, cutlery, etc.,

• buffet, a type of dresser, intended to be laid with occasional meals,

• chest of drawers, a low cupboard with drawers for storing bedlinen and clothing,

• overhead cupboard, cupboard at the ceiling used for storing rarely used items,

• wall unit, a set of furniture that fulfils all storage functions and at the same time serves to divide rooms and

• built-in set, wall set of furniture, usually closed, used for storage.

Skeletal furniture is made of elongated elements with small cross sections, in the shape of a square, rectangle, triangle, circle, oval, etc., not closing space within it, e. g. chairs, armchairs, tables and flower beds. The shape of the cross sections of these elements determines the next division of frame furniture into:

• beam furniture, in which the cross section of elements is a polygon and

• rod furniture, which is built using elements of circular, ellipse, oval or similar to circular cross sections.

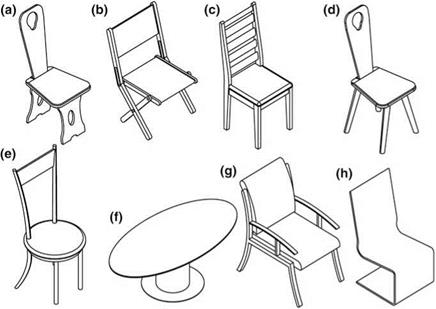

Depending on how the seat or worktop is supported, we can distinguish furniture of the following designs (Swaczyna and Swaczyna 1993) (Fig. 2.14):

• board,

• cross,

• with rails,

• without rails,

• frame,

• column,

• rack and

• one piece.

Furniture of a board structure is made mainly from elements cut from timber (ready part) or by gluing friezes in the direction of their width and then cutting out the desired shape. The base of the furniture piece is made up of board elements, the width of which is several times greater than the thickness.

Furniture of cross-structures is made of beam or rod elements joined by hinges and slides. Usually, this construction enables folding and unfolding the piece of furniture both in the direction of the width of the seat and in the direction of its depth. This lets the seat be made of textile or leather materials. In this type of

|

Fig. 2.14 Division of furniture depending on seat or worktop support: a board, b cross, c with rails, d without rails, e frame, f column, g rack, h one piece |

construction, only axial and transverse forces are transferred through structural nodes; therefore, high strength of wood against bending and torsion is not used.

Rail structure, as opposed to cross-construction, in the vast majority of cases, is inseparable. Thanks to permanent joining of legs with rails, a spatial frame is formed, which transfers axial and transverse forces, as well as bending and torsion moments. Thanks to these geometric features, the stiffness and strength of furniture of rail structure is much greater than with a different structures.

Structure without rail is distinguished by the fact that the base of the furniture piece is legs attached directly to the seat panel or worktop of a table. Cantilever mounting of the leg and usually deviating its axis from the vertical line causes that very large bending moments work on joints, which is the cause of damages of connections.

Furniture of a frame structure under the seat or worktop has fixed frames, to which the legs are attached. Usually, the frame is made of bent-glued elements, and friezes connected in the direction of their length or metal sections. The legs are usually connected with the frame using screws. However, it should be noted that this method of connecting construction components does not provide permanent stiffness and high strength of the base of the furniture piece. Bolt joints belong to the semi-stiff group of joints. Therefore, they have better mechanical properties than hinged joints, but at the same time, worse than adhesive joints belonging to stiff joints. With the passage of time, the stiffness of bolt joints decreases both due to the deformation of the hole by the hard core of the bolt or screw and due to the minimal changes in the moisture of the wood.

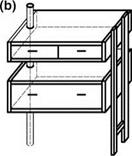

In furniture of a rack structure, the seat or worktop is attached on subassemblages that resemble racks. Usually, racks are made in the form of frames or rails connected to the seat with screws. It also happens that below the seat or worktop of a table, the side frames are connected with each other using front and rear rails. If bolt joints are not used, then the stiffness and strength of furniture of rack structures corresponds to the stiffness and strength of furniture of structure with rails.

The column structure of a skeletal furniture piece is distinguished by supporting the seat or table using one or two columns, which have been made in the form of turned wooden trunks, supported on legs or a plate, oval columns or multi-element supporters made of rods, strips or boards. Usually, the column enables to assemble in it a mechanism that allows one to change the height of the seat or worktop, as well as feeding cable lines connecting media to electrical devices installed on the table.

Furniture of one-piece structure is created mainly based on technologies of injecting plastic or natural fibrous materials. In furniture made of wood and wood-based materials, the technology of bending and simultaneous bonding of multiple thin layers of veneers is most commonly used.