Technical and economic requirements are characterised by their cost-effectiveness: design methods, structures of the product (material specifications), manufacturing technologies, method of validation, distribution, warranty and post-warranty services, marketing campaigns, etc. By starting to design a new product, all the criteria should be defined which enable making all possible savings, both during the design or manufacture of the product and during the exploitation by the customer. Guided by the purpose and place of use of the product, the designer should limit the selection of costly and durable materials only for elements and subassemblages, which have usable significance, with which the user will be in direct contact with or to those which may determine the strength of the furniture piece. Depending on the type of market group of customers, the cost of production of furniture can be minimised by using cheaper fittings, material substitutes or alternative technologies.

In a market economy, all activities are oriented to optimise the quality of the manufacturing processes, in particular the reduction of the costs of a full design – construction-manufacturing cycle. In design and construction offices of furniture factories, expectations related to form usable function and structural solutions are usually maximised, forgetting about the strong connection of technological innovation with the final cost of technical manufacture of the product, which is the essence of market success and prosperity both of the products, and their manufacturers.

Furniture design is a process of selecting geometric, material and dynamic constructional characteristics including the aesthetic, technical, technological and economic existence of a product in terms of appropriate criteria selected based on the principles of construction. The aim of a scientific study of the costs of construction is to search for logically organised relations, addressing the impact of structural properties on costs, which will enable to formulate the principles of construction.

The processes of designing and constructing furniture have a layered structure with the gradual transition from abstraction to specifics at different levels (functional, physical impacts and processes, as well as a description of the material form); hence, the most difficult are the initial phases of formulating the task for assessing the minimum costs of planned production. A relatively small number of known structural characteristics of uncertain and complex impact on the cost of the finished product make it difficult to reach a compromise of technical and economic criteria.

In design methods with early recognition of costs, designing should be combined with construction catalogues, catalogues of costs and an analysis of values. In this way, for each of the constituent functions, the best economical form of realisation of an element or subassemblage can be chosen, e. g. type of material, type of connection and technology of implementation (Branowski et al. 1985; Snijders et al. 1995; Stockert 1989).

Calculating the cost of future products must be closely linked with the methods of their calculation commonly used in the industry, carried over in environments of integrated computer-aided design (CAD)-enterprise resource planning

(ERP) systems, supporting the design and manufacture of furniture.

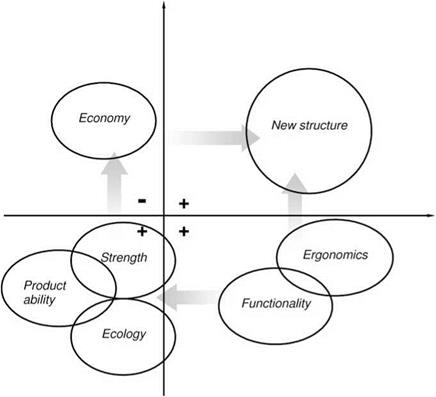

The construction of furniture is a concept activity that seeks to meet the set demands in the best way possible at the given moment. The laws of the market require that today’s products meet customers’ wishes in the most optimal manner possible. The degree of satisfying the numerous and partly contradictory demands and expectations to a great extent depends on the constructor (Fig. 3.6).

|

Fig. 3.6 The requirements accompanying the creation of a new design of a furniture piece |

Meeting the marketing challenge of long-term competitiveness forces to minimise the relation of outlays to the effects, which for furniture products can be reduced to the principle of satisfactory quality at minimal own costs.

The analysis of value is a planned process aimed to achieve the required functionality of a product at the lowest costs possible, without reducing the quality, reliability, efficiency and worsening the conditions of exploitation and delivery. This is a proven method in practice, especially useful when designing new technical and organisational solutions concerning marketing, organisation, construction, technology, quality, inventory management and sales.