Monitoring work is a typical example of a task causing a low level of loading. The tasks need an operator’s level of attention to be kept relatively high, while at the same

time there is relatively little for the operator to do and very little is happening. This is usually known as vigilance work. It is typical of vigilance tasks that performance drops significantly after only a short time at the job.

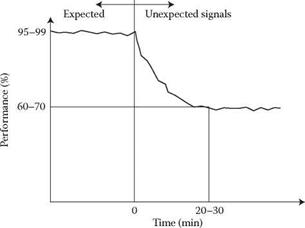

Figure 10.14 shows the performance ability in a typical vigilance working situation. In the alert situation, where there are plenty of signals from instruments and test lamps, the number of signals read and detected correctly may perhaps lie in the region of 99%. If, on the other hand, there are few signals, and these arrive randomly and are weak, the performance will start to drop considerably to 60% to 70% of its original level after as few as 20 to 30 minutes. The characteristic of the vigilance working situation is that the number of signals (such as relevant pointer movements and alarm signals) is very small. In addition, the signals are relatively weak and irregular. A common feature of control room work is the monitoring of signals that occur seldom and irregularly. On the other hand, the strength of these signals may be relatively powerful. Performance may thus be consciously raised by making sure that all important signals are particularly clear-cut. The risks occur when, for example, one has to be attentive to small changes on an instrument pointer. If such small changes are important to the operator, they should be provided with alarms. In this way, the special problems associated with vigilance can be avoided.

In a control room, work loading is commonly very low, often lying below the level required for the job itself to provide a certain degree of stimulation and alertness. Occasionally, however, there are peaks in the loading. These peaks are sudden, often cause load levels well above the suitable level, and are even sometimes above the handling abilities of the operator (see Figure 13.5 in Chapter 13). Peak loadings usually occur in conjunction with some form of disruption in the system. Lower

|

Alert performance Vigilant performance

FIGURE 10.14 The ability to perform a vigilance task can be kept high where signals are expected (so-called alert performance) but drops rapidly when signals are not expected (vigilant performance). |

levels of increase occur with different types of recording and reporting work, for example, during the start-up of the installation.

It is difficult for people to cope with these sudden peaks when disruption occurs. The difficulty is also greater because the previous loading has been at a relatively low level. These factors produce a lowered level of readiness to handle the loading peaks. If instruments and equipment are unsuitably designed from an ergonomic point of view, or there are different types of environmental loading in the room, such as glare from lighting or disturbing noise, these will make it even more difficult for people to cope with the sudden peak loads. Good environmental design and suitable design of instruments and controls in accordance with ergonomic principles make it easier for the operator to cope with these peaks. It is better to try to reduce the size of the loading peaks so that the operator can organise the tasks into an order of priority during peak load. The working situation should provide clear indications of the jobs to be done first at such times.

Work with a very low level of loading is experienced as being monotonous. But there are also other reasons why jobs can be felt to be monotonous. If the variations in the tasks are low, they will be experienced as monotonous even if the loading level is relatively high. Such is often the case in control room work. In order to raise the loading level in the control room, it is common for the operator to carry out various supplementary tasks, such as reading off and recording from various instruments or filling in various reports and log sheets. However, in themselves, these tasks are rather tedious and are felt to be monotonous. Thus they do relatively little to increase operator alertness. Such tasks should not be expected to aid increased efficiency or job satisfaction.

Supplementary control room tasks given to raise the loading level during low – load periods should be work that provides sufficient variation for the operator. It is important for the extra tasks to be relevant and they should not interfere with other parts of the job. These additional tasks should preferably prepare the operator to cope with the workload peaks. In practice this means that they in some way allow the operator to work on the system and the process. For example, planning work regarding future running of the process may be suitable. Certain maintenance and service work in the process or control system may also be meaningful.