Any study of Boston bombd furniture is dependent upon correct identification. Since few examples bear labels or other inscriptions identifying makers, a dose inspection of the inner construction and identification of the d і Accent woods is as necessary for the full understanding of a piece of furniture as is the analysis of the exterior proportions and design.

Tile construction of American bombf furniture bears out the

|

|

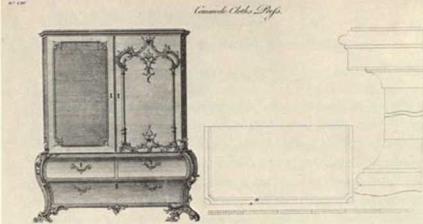

116, Dfsius fo* A Commo»£ I’bess. From Thomas Chippendale, Tht Gnitknum and Cabinet Makers Штшот, plan: civ, London, 1754, (The Henry Francis du font Winterthur Museum Libraries. J

|

|

117, Commode, Made by John Cobb, London, 1771, Satin wood, hare wood, mahogany, and ormolu; n. JJ inches, w, 39 inches, n, 24Vz inches, (Victoria and Albert Museum, London.)

|

|

|

|

|

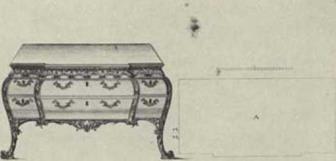

lid Dhicn fob л Fbincii Commods 4’лйт. я, From Thom» Chippendale. Thr Ccnilmatt and Cabinct-Maiter’s Dinttot, ріік xuv, London, 17J4, (The Henry f rands dq Ропі Winterthur Museum Libraries.) |

Tradition that it was made in Boston or certainly in nearby areas that used the same woods and traditions of craftsmans]]ip. While the primary wood is mahogany, the secondary wood is ordinarily Ph»u strcbtis, or white pine, the wood so favored by Boston cabinetmakers. The small differences in constTuction—size and number of dovetails, type of moldings, direction of the grain in the bottom of drawers, etc.—Can serve as a guide to the identity of the cabinetmaker. The wide variance found in such details in bombd furniture belies the dieory that the form was ihe specialty of only one or two shops. In fact, die names of six cabinetmakers have been linked to American bombtf furniture and the list must include at least twice as many as yet unidentified men.

Boston bonrbi furniture is understandably unified in its general

|

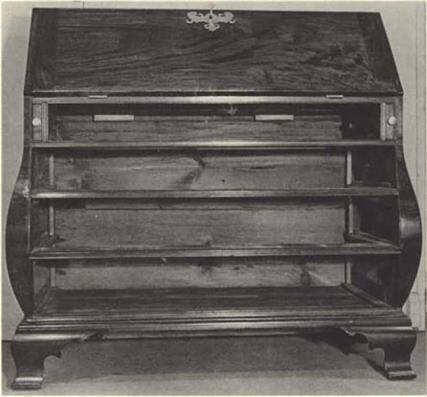

119. T NT]: n[Oh Ol= DrsK. Stamped “G. САШЕ.*’ [The Hennage Collection.) See also figs. 108 and 1 JO, This df lit it dn ґхйтрІе With jIraighl-j:Jof JrautrS. |

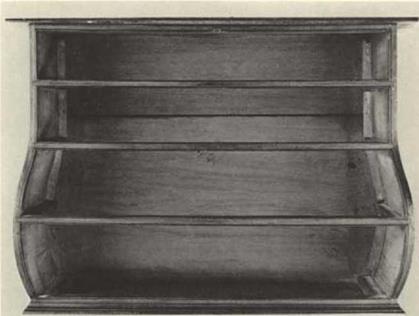

construction (fig. 119). The sides arc cut from solid pieces of mahogany. The front tails, also mahogany, ate dovetailed into the sides; in most cases, a strip of white pine is glued to the back ot the rail for added strength and economy. A complete set of solid dust boards is rarely found, but in the traditional Boston maimer the rail and attached secondary wood average about six inches in depth. Occasionally a single solid dust board is placed between die second and third drawers to strengthen the sides. The back is composed of vertically or horizontally lapped white pine boards nailed to the top,

|

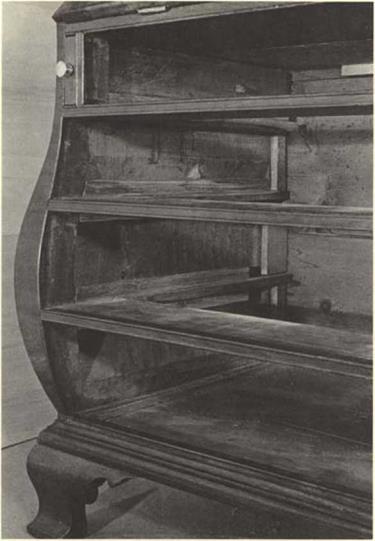

120. Detail oe Desr Imtejuoh, Stumped "G. CADE." (The llcnnagt Collection.) See also figs, mu and im. |

sides, and bottom. The bottom, also composed of white pine boards, is either flush with or set down from the base rail. Additional strength was provided by glue blocks of various sizes and shapes between the sides and the back, and sometimes between the sides and bottom.

The major differences of BostOfi-эгсэ bomb£ work arc found in the construction of the bombe itself, which can be divided into two major categories and assigned a chronological order. The earliest and least sophisticated method can be seen in the a753 froth iiigham desk (fig. 97). In casepieecs of this type, the bulge is contained wholly within the solid mahogany sides. The interior of the bulge is either roughly hacked our to allow for wider and stronger drawer supports or simply smoothed to the vertical surface found in traditional casework construction (fig. tso). Drawer sides are straight in the standard manner; the bombe shape is encompassed only in the forward bulge of die Iowct two or three drawers. Bomb£ furniture with straight-sided drawers is the rarer of the two major methods of construe tion, appearing on about fifteen percent of known American bombe furniture. Since six bombe casepieecs with firm dates before the Revolution are constructed in this manner, it is undoubtedly the earlier type of construction. Many desks and bookcases of this type relate stylistically to early eighteenrh-century design in the retention of die vestigial molding separating the desk portion of the case from the drawers m the manner ot the earlier desk-on-frames. The interior arrangement is usually in die Queen Anne rather than the Chippendale style. The doors of the upper sections have rounded arched panels in the manner of the Queen Anne style, and there is often little or no carving.

In the second major category, the curve of the case side is echoed in die curved construction of the drawer side (fig. 121). This method of construction is basically the same as the earlier method with the exception that the solid pieces of mahogany matting up the sides are cur out on die inside to follow the ex tenor curve. The drawer construction therefore differs by the inclusion of curved sides built to fit the curve of the interior shape of the casepieec.

Although the curved sides of the drawer require greater sophistication of craftsmanship, that fact alone would not necessarily imply a later date. While the majority of bombd casepieecs have curvedsided drawers, few can be dated prior to the Revolution. In addition, the aesthetic sense of the second type of ЬопіЬй is more highly dc-

|

121. iNTFkios of Chest of і>иліьі:йї. Salem. [The Henry Francis du Pom Wimer – thur Mine urn,) See also fig. ijij. This chtst is dii example with curved-sided drou’Cts. |

vclopcd, When viewed from die from, die curving line of die drawer sides gives a unified and organic movement to the boinb£ bulge that is disrupted by the straight line of the straight-sided drawers of the earlier type. Most of the bombd furniture with curved-sided drawers is more developed in the Chippendale idiom, with details such as dentil molding, Chinese fretwork, rococo carving, and, in a few cases, serpentine fronts.

Bodi types of construction, the curved – and straight-side^ drawer techniques, arc found in a rare bombe form, the dressing glass (figs. 122, and In both glasses the concept of design is unified [60]

|

122. Dbessinr Guji, Вайшье; 17 S5“i 7 Bo. Mahogany and white рівг; n, jjJ;H inches, w. l-K-3 j inches, !>. 5V1 inches. (The Henry Francis du Pont Winterthur Museum.] |

through the echoing curves of the spiral supports anti bom lx1 base. This particular unity of curvilinear form and detail is a hallmark of lloston bombd cabineework, in desks and bookcases the curve of the bombtf Sides is often repeated in the Ogee bracket feet or small cabriole legs, in the door panels of the upper section composed of continuous ogee curves, and in the swan’s neck pediment. In a few of

|

|

123. f> R E s я n g G t л s s, Salem area. c. 176y-1780, M ahogvuiy and whi re pine t tf. ifl3/* inches, w„ 18% inches, d. 9% inches, [‘the Henry Frmds du Pant Winterthur Museum.]

the more ambitious examples, a serpentine curve is added ю the front of the base, incorporating the bombe and serpentine curves itito a powerful three-dimensional form (fig. 135}.